A simple rotary table for working mirrors, homemade with some carpentry tools for the construction of the structure, while the electrical and motion transmission components were obviously purchased.

the peculiarity is that a classic a cell is mounted on the surface 18 support points capable of supporting meniscus curved mirrors during rotation.

Meniscus curved glass has advantages in terms of weight and workability, although as we know, the reduced thickness does not help rigidity and containment of deformations, which are superior to mirrors with generous thickness.

On the other hand, for an amateur glass scraper, it would be almost impossible to work and move mirrors from 80 cm in diameter or even more, therefore it is a compromise that can be accepted if you want to experience the thrill of working large diameters.

The rotating table has a diameter of 81 cm and is made from a phenolic-glued birch plywood panel with the addition of several layers of water-repellent protection specific for wood ( vitrifier ). A simple self-built cell for mirrors is mounted on the surface 60 cm, but it is possible to mount cells for mirrors with a diameter of up to one meter, always meniscus and of very limited thickness.

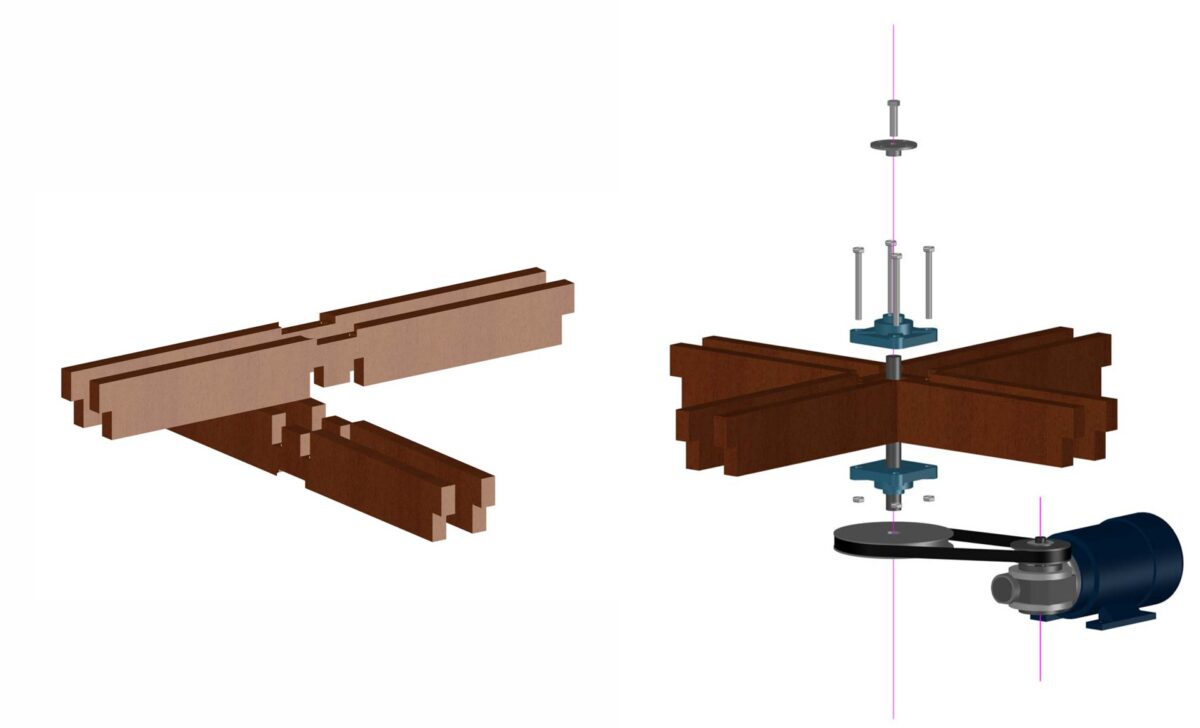

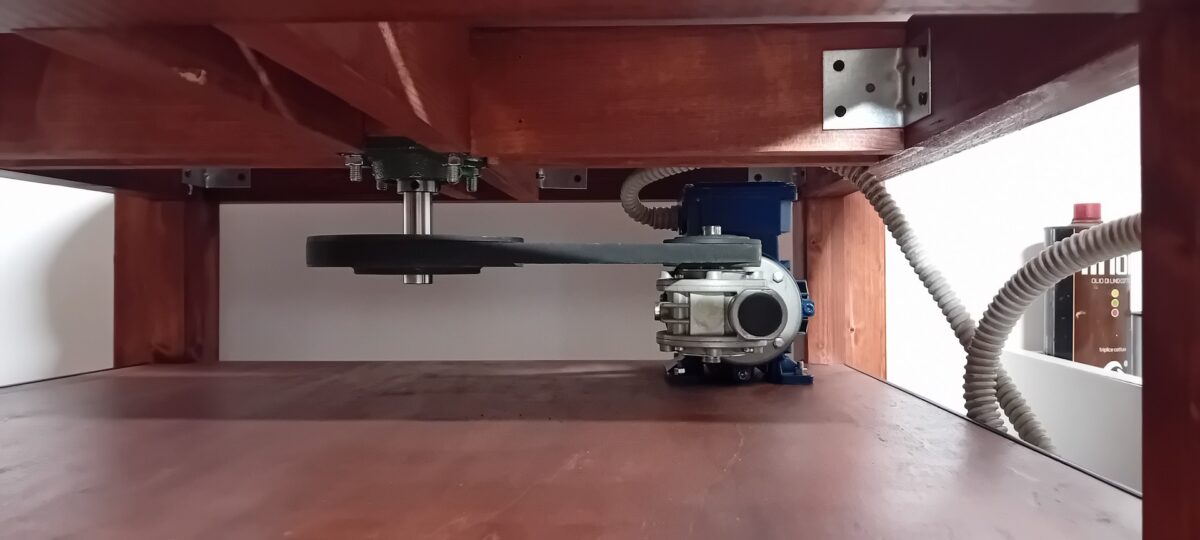

The plane is fixed to a tree 20 mm diametro, mounted in turn on two self-aligning bearings. A "truss" system allows the bearings to be housed and tightened to the structure.

A three-phase electric motor with inverter and speed regulator, ( a used industrial one kindly offered by a dear amateur astronomer friend ) it is connected to a system of two pulleys for the connection and transmission of motion to the shaft, as well as for a further reduction in the minimum rotation speed which, as we know, it must be very low to allow semi-manual processing of a mirror.

Three wheels with bearings support the rotation of the table top, the wheels are perhaps a little undersized, in fact they have a maximum load capacity 15 kg each. Maybe they should be replaced, not so much for the weight of the glass being processed but for the added thrust that is applied to the tool in the roughing phase but, Fortunately, the meniscus shape allows you to skip the roughing phase, as the glass is already curved to size and only requires finishing with abrasives to obtain a correct spherical shape.

Below is the video of the minimum speed sustainable by the car with a meniscus from 60 cm in diameter and 19 cm thick curved to F2.2