The material issue to be taken to build one for telescope mirror is quite fascinating.

If you start from a hypothetical initial question (of which we do not know a priori the solution) which is: If you have to build a mirror for a telescope, what material is more convenient to do so?

The most obvious answer and obvious that is to say today: "Glass", because they are obviously made almost all so, but if we this information we had not and it was the first time that you try to build one, how do you make an objective choice of restricting it to a few possible candidates ?

Well, initially they analyzed and decide the essential requirements of the project, kind: minimize the mass of the component deformation equal ... etc., after which further refine the selection by applying more stringent requirements for the project.

As for one for telescope mirror, you can start to narrow down the choice this way:

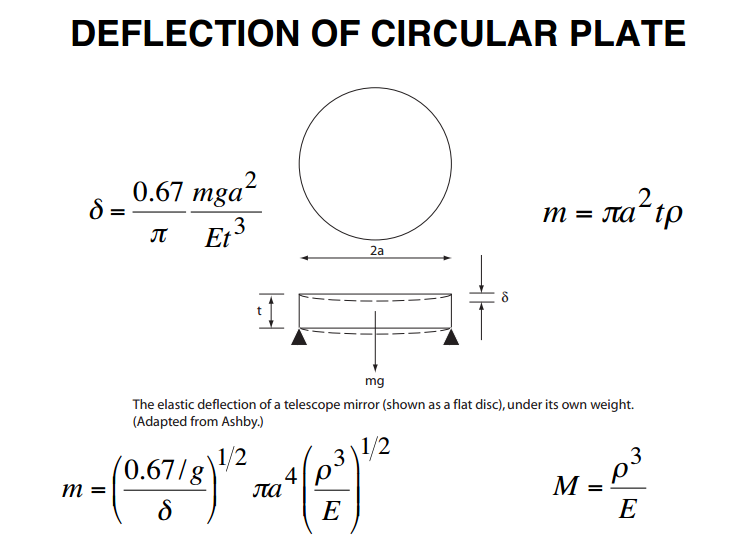

In the image are indicated above two equations, the first which expresses the deflection of a homogeneous disk subject to its own weight (top left) and the second, which expresses the mass of the disk as a function of its volume by the density (top right). Going to combine together the two equations and esplicandole as a function of the total mass, It is obtained by the equation at the bottom left.

If we look at the terms in this equation we see that are all geometric terms dictated by the form chosen for the disk except the two terms in brackets, that they depend instead on the type of material that will be chosen for the mirror. Since the equation expresses the mass of the glass disc, to minimize, It must be the minimum value in brackets (r³ / E), indicated at the bottom right as M.

Obviously minimize r³ / E It is the same as saying maximize its inverse, or E / r³.

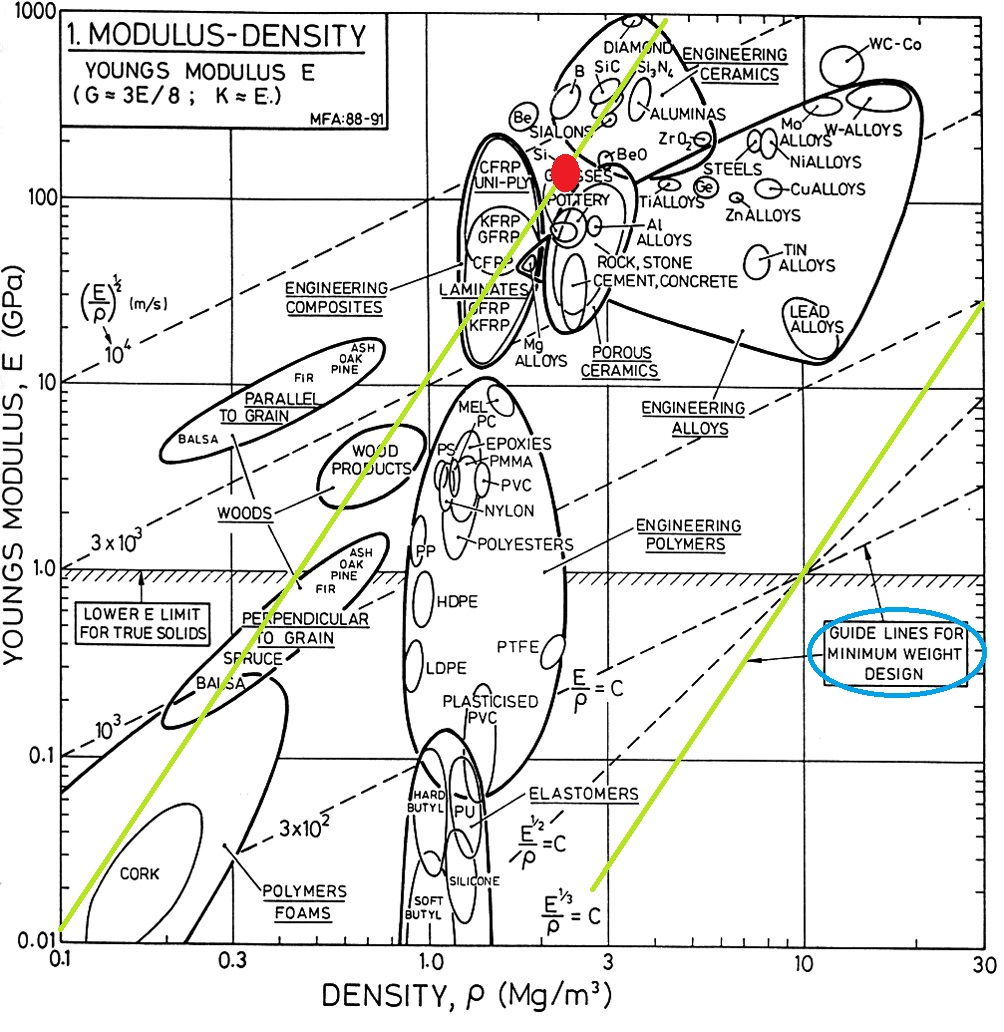

At this point we got an index with which we can compare with each other different types of materials, and seems to do so, It is relying on the maps created by Michael F. Ashby, and which are called precisely “Ashby maps”, that bring into the relationship between their two different physical properties of the various materials.

So for the analyzed case, among the numerous existing cards, you should refer to the one that relates Is (elasticity module) with p (density).

To properly compare the various materials, depending on the specific case that is being analyzed, We must move on the graph using the right angle between the guidelines indicated in the circle in blue. In this case the entity is to maximize the ratio E / r³ obviously equivalent to Is1/3/p. Then, using the straight line with the gradient indicated, You can compare between them the materials having the same specific ratio and then figure out which of them exhibit the maximum performance.

For a comparison, I placed a line passing just for the glass class (circulate red). At this point it is simple to appreciate what materials have better or worse characteristics of the glass. It is important to remember, however,, that here we are analyzing only the map that will provide us what are the materials that minimize the mass of the disc deflection parity, but it tells us nothing about other aspects, as thermal stability, processability etc., that will be features that will further refine the choice of material, After the initial screening.

Either way can be seen as silicon carbide, beryllium, CFRP (carbon fibre reinforced polymer) and some polymeric foams have the best performance of the glass, while it is also evident the reason for which they are not constructed metal mirrors (steel, aluminum, titanium…) which would be much heavier than those in glass.

Obviously, some choices the can be excluded a priori without having to investigate further, type diamonds (for obvious cost reasons, dimensions, workability ...), or the woods, which despite having high performance they are very dimensionally unstable under varying atmospheric conditions (temperature, humidity etc.).

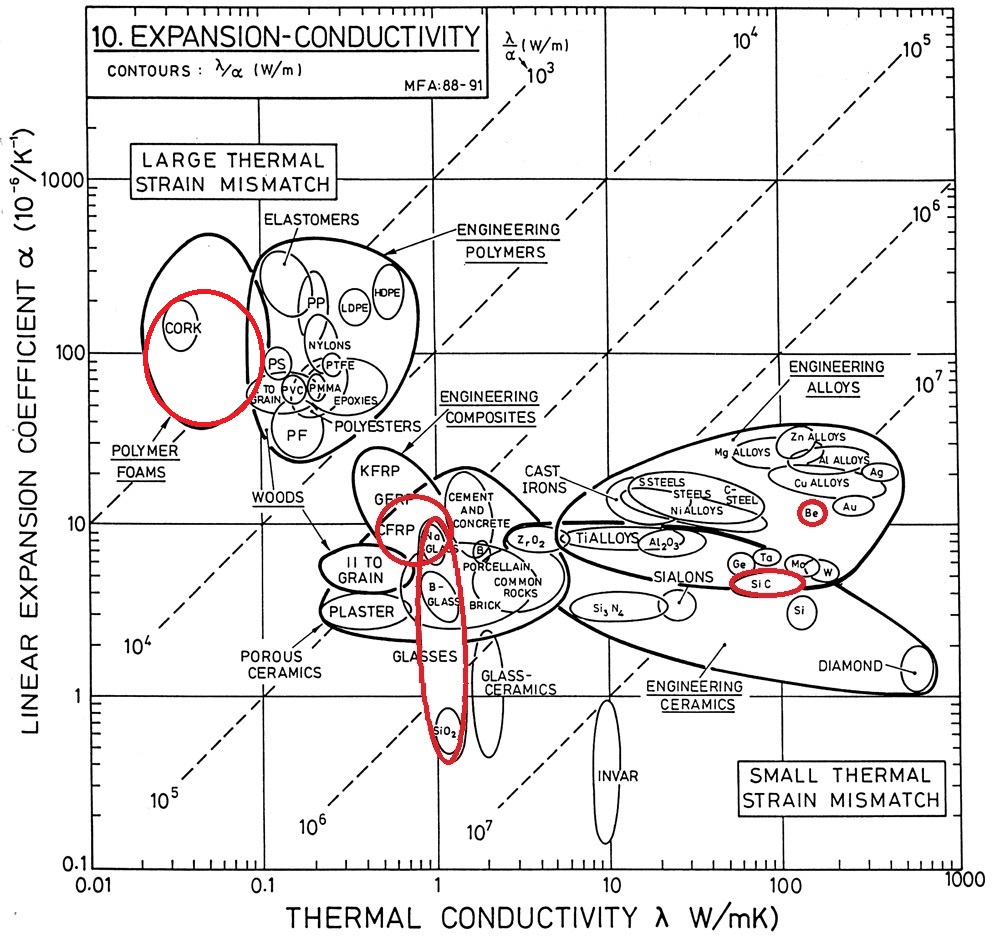

As mentioned before, this first choice you have to add a second screening that takes into account other limiting factors affecting an astronomical mirror, type thermal expansion. This again you can do it using a different map of Ashby, like the one below, which correlates the coefficient of thermal expansion with the thermal conductivity.

Knowing also the thermal conductivity of a material and not only its thermal expansion (that in a first approach seems to be the only important parameter) because it serves the same thermal expansion coefficient that has a greater conductivity succeeds in a better way to make the temperature uniform over the entire mass of the mirror.

For example, with a low thermal conductivity material, causes, if it were to be present a thermal gradient inside the mirror, this gradient hardly tend to disappear standardizing the entire surface temperature, then causing internal stresses and differential contractions in the same mirror.

In the map we have been highlighted 5 types of materials that had been voted the best from the previous screening. Through this map it is possible to note such as polymeric foams present a low relationship between thermal conductivity and thermal expansion, not very high that the absolute values of the coefficient of thermal expansion, thus excluding them from the possible candidates for the construction of an astronomical mirror.

Silicon carbide and beryllium instead, They have roughly the same relationship between thermal expansion and thermal conductivity even if the silicon carbide has a thermal expansion coefficient well below.

The glass class stretches over a wide range of values with regard to the linear expansion, although the glasses for astronomical use are able to reach very low values or close to zero, making them among the best possible materials in this sense.

The CFRP instead possess an intermediate thermal expansion coefficient between that of SiC and of beryllium and decidedly worse than glass while being comparable with them for thermal conductivity.

By observing carefully this map, is known as the invar is by far the best material from this point of view, associating high thermal conductivity at very low values of thermal expansion. These properties combined with excellent mechanical characteristics make it an excellent structural material for space telescopes, which often employ in their components. The high density, however, limits its use to a minimum.

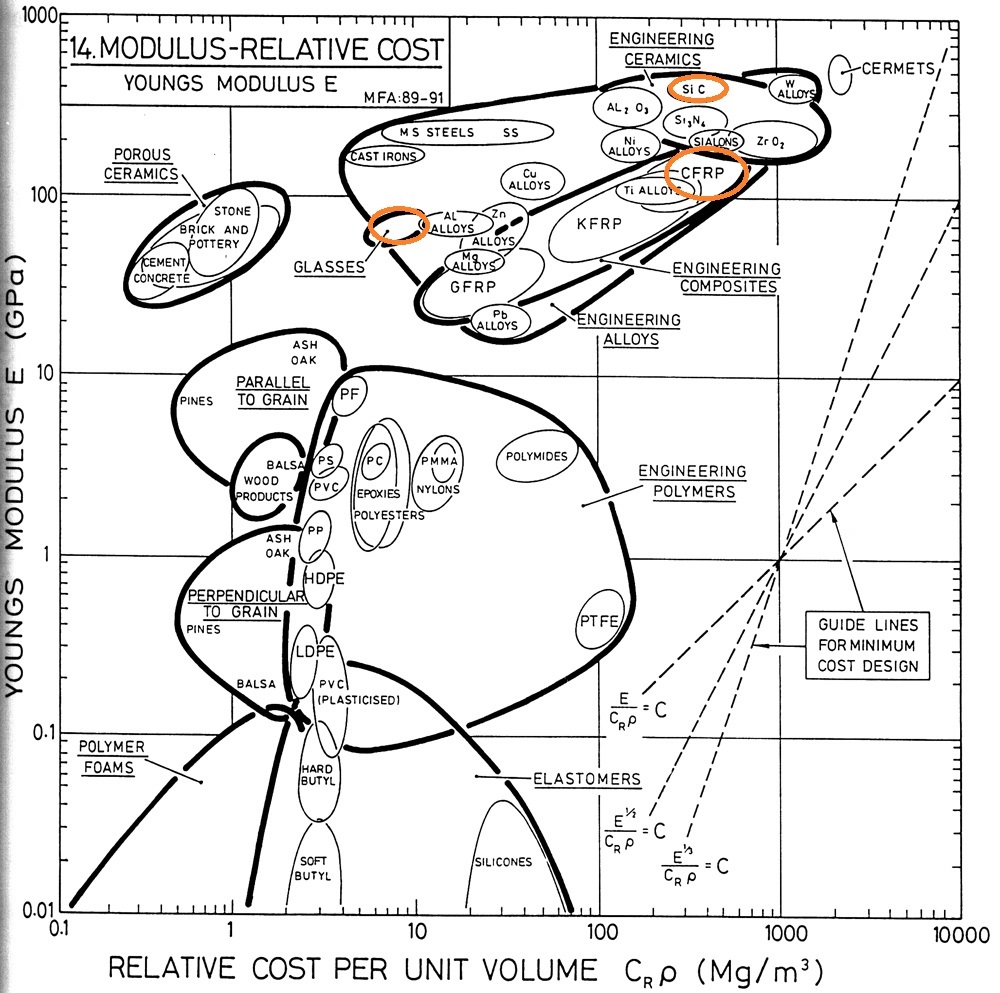

Ultimately, but not the less important is the question of cost. Looking at the following map, you can make a rough idea of the costs involved for each material:

Summing:

GLASSES

the last table shows once more, because the glass is still the undisputed masters of the scene when it comes to mirrors for telescopes, given their extremely low cost compared to competing materials, not forgetting that still have good or excellent properties in all aspects analyzed. Glazing as l 'ULE or other glass-ceramics have thermal expansion coefficients close to zero as well as a good relationship between E / ρ³ which makes them particularly suitable for both terrestrial telescopes that spatial. Examples are all major terrestrial telescopes, l’ Hubble space telescope, HiRISE and a multitude of other instruments.

SIC

The silicon carbide is one of the best materials in absolute for an astronomical mirror from a mechanical point of view, even if it has thermal expansion values not to the levels of the best glasses. The density slightly higher than that of the glasses do not, however, limits the use of this material having a high ratio of thermal expansion and conductivity, which makes it very suitable for space telescopes, which greatly suffer from the different thermal expansion between different materials in contact with each other, whose differential expansion induces harmful stresses in the structure and in the mirrors. The SiC being also often used as a structural material for the carrier plates of space telescopes would pair perfectly with the mirrors and their supports, that they also can be made of the same material, greatly simplifying the system design. Glass mirrors are often the norm even in space telescopes, but their different thermal expansion with respect to their supports, made in another material, involves having to be given to appropriate systems for compensating the deformations so as not to induce additional tension in the mirrors, which would decay in performance. For example the largest space telescope in orbit today, l 'Herschel Space Observatory has a mirror 3.5 m f/0.5 (operating in the far infrared wave lengths) it is done in SiC, as well as all the mirrors in Plank probe and those of many other probes still.

CFRP

Their high ratio E / r³ makes them excellent candidates from a structural point of view for an astronomical mirror, and in fact in the past it has been several attempts facts and studies to test its feasibility in building , although to date mirrors so facts they have not found wide use in the wavelengths optician.

To their detriment goes the coefficient of thermal expansion, which limits its dimensional stability with varying temperature, of paramount importance for optical applications, although the continued progress in this type of material, It has already led to the development of solutions having very low values of CTE, perhaps opening doors, to a future (maybe not too far away) Revolution.

Their high mechanical performance, views in the first map of Ashby, It would make them the materials that most of all limit the total mass of the mirror, and this explains why they are widely used in the construction of radio telescopes. An example of this are the antennas 12 meters of’ ALMA (radio waves), but also the primary mirror of 1.5 m del Planck space observatory (infrared and submillimetre) it is a famous example.

BERYLLIUM

He does finally head into the list, also a member of the class of metallic materials. Unfortunately beryllium is considered a carcinogen for humans and its workability need for specific rules and controls. As we saw in the first Ashby paper, it is absolutely one of the materials that minimizes most of the total mass of the mirror, although its high coefficient of thermal expansion matched to high production costs and the drawbacks due to its toxicity they have greatly limited the spread. Things change dramatically, however, when it comes to cryogenic applications, or for those devices that must work at temperatures close to absolute zero.

At temperatures lower than the 80 K the coefficient of thermal expansion of the beryllium in fact is reduced almost to zero, and the mechanical properties remain very respectable making jump in the first place for its thermo-mechanical qualities for astronomical mirrors. Clearly the cost and dangerousness of the material, however, it limits the spread, but it is no coincidence that the largest, expensive and complex telescope that has (by now) ready for launch in space is chosen beryllium as the material for the mirror construction. Of course you are talking about the James Webb Space Telescope.

Another famous example of telescope, operating in the infrared, with its ritchey from chretien 85 cm with optical beryllium, It is the Spitzer Space Telescope.

Is’ however be borne in mind that screening done in the article is very preliminary, certainly gives some good general guidelines, but it does not take into account many other factors which in reality should instead be taken into account, type workability, degree of polishing that are unable to reach in particular material, production process necessary etc ...

Despite this, however,, it is interesting to note that with only two simple tables has been possible to determine the best candidates critical assessment materials for the construction of a telescope mirror to, and how these results later, faithfully reflect actually adopted solutions, These result of decades of research and testing.

a special note should be made for ceramic and composite materials, these types of materials are having very rapid evolution in recent years, with the continuous production of solutions with amazing properties, and will not be surprising, if in the near future, these types of materials you are going to always assert more both for space telescopes and terrestrial.