Surely, especially at the first mirror, if they can do many more, I limit myself to this because besides being quite common, to the “experienced” personally and I guarantee you my mirror does not at all acceptable…

Some of these conditions have general validity, even if they become particularly important during the phase of parabolizzazione, certainly the most delicate phase, in which an unwanted event may force us to start, dividing the sphere.

So who is preparing the first parabolizzazione may organize and better check your setup, those who are already expert, perhaps he will fondly remember his first “back to the sphere”…

1 – STARTING FROM A “BAD” SPHERE

it might be thought:” what good is a perfect sphere, then if I have to change it ?”

It's actually one of the most frequent mistakes, also looking into the network the various constructive report, one sees how the surface anomalies and irregularities then remain even during the parabolizzazione and sooner or later we come to terms !

Since it is much easier to correct a ball from a shot back edge, a central hole, an astigmatism or a deformed crown, how having to do it on a dish, best done before risking then find it impossible to correct the error without having to return… the sphere of origin.

2 – PATINA OF PITCH TOO HARD

The “Sword of Damocles” of us users of rosin and beeswax ! ( the “Gugolziani” have life easier ! ) Here you might think: “when I arrived at the sleek and ball with this tool, why should it not be good for the parable ?”

Because the sphere is by definition ( together on the floor ) the only figure that allows two surfaces to remain always in contact at every point, however, the move over one another. If we were able to tailor the coating of the mirror polishing during long sessions, it is said that we can do it with as much security during parabolizzazione where, every session we will see our surface deformed away from the ball. A hard coating , although it seemed fine for the Ball, succeed with more difficulty adapting to the new shape during processing, introducing various zonal errors at the points where the contact will be better.

3 – ADAPTATION NOT OPTIMAL

For the same reasons, even with the right hardness of the pitch, the adaptation is the key priority, the fundamental test before any session. Even a small variation in temperature, a previous session slightly’ more “pressed”, scrubbing power, a remake of the channels, alter the shape of the tool by introducing deformations that, although not visible to the eye, They are definitely much higher than our tolerance range. You will never get tired of putting pressure on tool and mirror before each session, by applying an appropriate weight and waiting all the time necessary so that the patina fits as much as possible with the mirror.

Sometimes it may seem that the tool “slipping away” almost without friction on the mirror and one is led to exert more pressure to have a more effective sliding, or excessive friction leads us to having to exert an abnormal thrust in order to move the mirror or the tool. In these cases you have to check the fit, the proper fluidity of the mixture of cerium, and avoid the thrust and the excessive pressure that would deform the surfaces in some areas, creating surface roughness.

4 – LITTLE COMMON MEASURES

Do not wait until you get near the end parable for accurate measurements, indeed matches the earliest stages of processing with past W, trying to control their development.

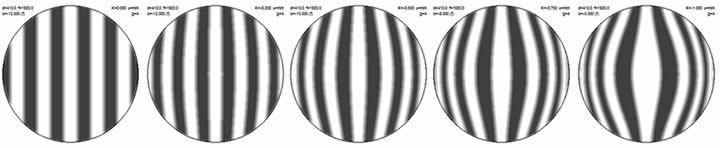

Use charts simulated the Ronchi setting constant conical step -0.1, try to work out the perception of the bands, the tendency of the more or less accentuated curve in some places rather than others, until you can confidently compare the simulation with your tests.

Being able to tell if you're at a constant conical -0.5 instead of -0.6 It is a useful exercise in preparation for the final phase and at the same time can put you in the notice whether some area is deforming as quickly or slowly than others. After successful completion of ” mid parable” that is, the conic constant -0,5 Foucault will be our constant companion along the course Ronchi.

Fig. 1 – Example of a sequence of parabolizzazione increments of constant conical.

5 – HAVE NOT CLEARLY IN MINDS WHAT WILL’ DO

Is’ a direct consequence of the previous point, if not training their visual perception to detect the slightest change of the figure, and put in relation to the technique or to the condition that generated it, It is likely to proceed to trial without being able to intervene at the right time and in the right way. It almost always start from a series of sessions with racing W, in some cases ( rare and very lucky ) only those will be sufficient to end the parabolizzazione, but they are unlikely to be made all in the same way and under the same conditions, So always keep a log of each session, write time, Implementing Rules, amount of abrasive, extension handle trajectories and pressure variations of the races and annotated or defects found on the surface through the test. Without realizing it you will build a “library” of techniques , possible errors of execution and their resolution will be an important source of supply when you are looking for a solution to a new problem that will occur.

6 – ENVIRONMENTAL CHANGES IN TEMPERATURE AND MIRROR

Surely no one would dream of working with sub-zero temperatures or forty degrees in the shade, the optimal temperature is the one that the common sense suggests, between 20-25 degrees, but more important is that the value of the constancy of the temperature in the environment of work between the various sessions. Differences in temperature between a session and the other modifying the surfaces and the effectiveness of the processing just enough to bring unexpected results and unwelcome…

For the same reasons, Avoid doing any test immediately after washing the mirror at the end of session, use the same precautions that you would use for an optimal observation telescope: wait for thermal equilibrium !

7 – POOR CLEANING

At these levels of machining precision cleaning it is never enough, even dust can create unwelcome side effects on the surface of the work, while even a hair can do damage…

8 – POSITION OF THE FINGER NEAR’ EDGE LOWER

As I mentioned in another article, It may seem a pittance, but the amount of heat that the fingers, if positioned close to the edge and then in the machining surface , They are able to transmit to the glass, It is sufficient to expand the volume of the mirror locally, just enough to alter the shape beyond the tolerance values. In other words, we're going to work an outside area that is rendered "highest" from the heat added during the past. 're finished the session and reached thermal equilibrium again, You will be left with a lower outer area than it should be.

therefore, especially if the mirror is thin, Always use gloves.

9 – SPEED’ OVER RACING

I will not hide that in my first machining grattavetro, I thought speed races would serve to… finish first ! I think it's one of the most serious mistakes to avoid, It not only does not speed anything, indeed it slows, but unable to perform the main function to our abrasive that works thanks to the right dosage of friction and heat generated, excessive speed can lead to either have no effect on the “strips”, real deformation of surface roughness.

10 – POOR ROTATION OPERATOR / TOOL / MIRROR

Yes I know, many will think it got to this point, the operator and the tool rotation is now what acquired. Do not be so sure, during parabolizzazione making both short sessions that long, with or without pressure, with full diameter or with sub-diameter, the possibility that a work area in a different way with respect to another is much greater ! therefore often changed and so continued, position , rotation is that your tool, if you are too precise're messier in doing so, if you are too messy, be more specific, if you can generate a “ordered chaos” your mirror will thank you.

If you have the attention to check that there are no such conditions, you will have the opportunity to focus on parabolizzazione , on the application of techniques, on testing and the consequent corrections of the shape, until the final result which, not long in coming.

Good parable to all !

Bartolomei Mirco

massimar