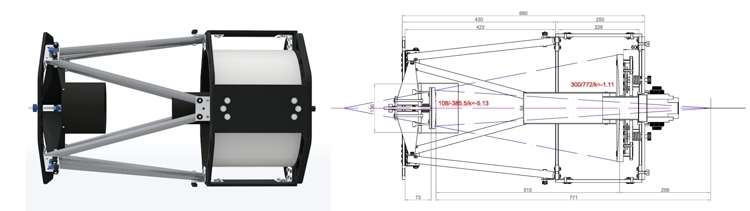

Fig. 1 – Render and section of a hypothetical telescope RC

And, it's possible to do it (*) by manually working the optics and you don't need special equipment or more sophisticated than what we normally use for the construction of a parabolic mirror but, let us now, to embark on such an adventure necessarily have to have more than one working behind, to understand how to generate two hyperbolic surfaces, It must have fully understood the construction of a parabolic surface.

At that point, paradoxically, we realize that attaining a good hyperbole ( for the primary ) It will also prove easier than to build a good dish but it would be enormously difficult and labor intensive, try to do it without ever having faced the normal construction of the parable.

So from now on we will give acquired for all concepts and techniques necessary for manual processing and testing of a parabolic mirror to short focal, avoiding to dwell on these to deepen again as meet during the journey, not much to tell the truth, but of fundamental importance for the understanding and the success of the project.

We summarize, for convenience of the reader, what topics in addition to basic “classics” for a parabolic mirror ( Rough grind, frosting, polish, parabolizzazione, Ronchi and Foucault test ), They are to be considered in this preparatory processing and the discussion will refer to the dedicated pages:

- Use of sub-diameter

- short focal lengths Parabolizzazione

- Test caustic

- The secondary convex

- Interferometer Newton

- Analysis of interference fringes

WHY’ UN RITCHEY-CHRETIEN

They can be many good reasons for choosing this optical scheme, we are not going to list here, any fan of optical astronomy , He knows pros and cons of this configuration, But the aspect that most others can stimulate grattavetro is undoubtedly the challenge, The measure their skills with a major test and out of the ordinary, which has no fault tolerance, pitilessly that does not forgive the slightest inaccuracy constructive, is that the optics of the instrument as a whole, but that at the same time allows with great generosity to enter more fully in the world of processing of the mirrors, so that it can also groped to understand the deepest secrets.

However, the extreme optical precision required for these configurations, It could also discourage the most willing from undertaking a similar path therefore, We will try to provide some solutions, to identify a path that might make it more accessible to achieve a good result and, as we'll see, the self-builder is significantly advantaged with respect to a professional production of optical constrained to certain constructive parameters and, with a little’ of “opportunism”, we also benefit from the mistakes that inevitably will be committed during processing, amplifying in fact the range of possible tolerances for the verification of the optical scheme.

WHICH DIAMETER ?

We are dealing with two mirrors, closely linked in their respective size, distances and deformation by certain mathematical equations and, Contrary to what you may think, a mirror of small dimensions is more difficult to work manually with respect to a medium-sized, so we have to make sure that the secondary does not fall below 10:00 to 12:00 centimeters in diameter, worth an extremely complicated and uncertain machining.

One RC scheme with primary from 30 cm, It ensures a secondary between 10 e 13 cm ( as a function of the overall focal, back-focus and other parameters that will be discussed below ), therefore the primary mirror reference will be exactly 30 cm.

PRIMARY OR NOT DRILLED DRILLED ?

Fig. 2 – The mirror before and after drilling.

One can opt for both the solutions, the central hole does not prevent us to work the mirror with the usual techniques, the hole allows to realize the classical configuration and to observe from the back-focus, while the mirror can be used in non-pierced configuration Nasmyth, obviously with the addition of a third mirror diagonal plane.

If you are so maniacs comfort ( and collimation ) opt for the intact mirror and the diagonal plane, otherwise you can pierce the glass immediately ( making sure to use the part of cut glass as “plug” for the hole, during the roughing-grinding ) or you can pierce the mirror once it reaches the required depth, after use of the last fine grain in the grinding step, with lots of greetings to “plug” ( procedure I personally adopted ). Anyhow, the generous blockage of a RC allows us to realize the hole and not to cure us of the deformations in the vicinity of it given the size much smaller than the hole relative to the hood of the secondary.

In these articles we will describe the processing procedures in the case of a mirror drilled which can be easily extended to an intact mirror.

THE sECONDARY

The element “new” with respect to the construction of a Newton it is obviously the secondary convex mirror and hyperbolic. Also, and especially for the secondary you must have acquired at the bottom of all the processing usual techniques, to which they will be added other necessary information for processing the convex mirror, but in this case, processing can be dealt with for the first time in this seat.

A rule that can be defined immediately ( Then we will see why ) He tells us that In a Cassegrain scheme is that the secondary must be built on the primary, It means that we worry to reach in case of an RC, a primary hyperbola that verifies the optical schema, although it will be slightly different than at the draft scheme, but once “fixed” primary, then it will be the secondary that “fit” now, then we will always have the possibility of making the secondary ( we can afford all of the processing errors and we want to fix them ) up to perfectly adapt it to the primary in order to verify one of the infinite optical schemes RC, even if it were to be different from the original project.

THE METHOD

Fig. 3 – Setup of a possible Cassegrain configuration with software “Atmos”

As we said, a self-builder advantage is in fact that it is not bound to dimensions and tolerances relative to the telescope that will host the mirrors, because the tool still does not exist, It will be built later and tailored to the mirrors obtained.

This as we shall see, It would considerably simplify the whole process since we often found to have generated a good hyperbole for the primary, sometimes “casually”( but also for the secondary ) which, however, it differs from that of the project and its use would involve changes to all of the system parameters ( distance between the mirrors. focal overall, backfocus, etc ). But to do-this is not a problem , It is a resource, It means that the telescope project will be delayed in processing completed and mirrors, in case you reach a good hyperbole for the primary, It will use one even if they differ ( within limits ) in the values of the conical constant than budgeted.

It will mean that will be calculated a new configuration that checks the optical pattern and will be recalculated accordingly all new parameters for the secondary.

a practical example

those who have worked a parabolic mirror knows that during the approach to the parable, a bit’ fortunately, and a little’ for capacity, There is found to have generated some great surfaces, which, however, they differ from the parabola to a small value of the conical constant, in practice the measures of the generated curve does not “enter” completely within the tolerance zone for which, even if the performance of the surface is strictly by conic curve, the mirror is not parabolic and therefore not usable for the purpose.

Under this point of view, hyperbole may be more tolerant of the parable, as well as the value of K = -1 ( parabolic ), we are already in the field and hyperbolic, for a certain range of values, there is always a secondary verification that the RC scheme, so if during processing we happen to run into a hyperbola “perfect” K other than project, we will not have to do is check the software which checks the secondary RC scheme. If the secondary is not resulting “exaggerated” and it seems feasible, we can stop in the processing of the primary.

It would be different it was having to catch up with centesimal precision the constant value conical design, a long work and with no guarantee of success. But with this method, What you have to look for is to build a hyperbole as regular as possible, accurately measure the value of the conical constant reached and to adapt the scheme to it.

With this assumption we start from a primary “perfect mirror” for the project.

PLANNING

So we can define a schedule for the construction of our Ritchey-Chretien in this way:

- calculation of the optical scheme and the construction parameters for the primary and secondary with the optical design software

- processing of the primary towards the achievement of the hyperbola with the constant conical project

- tests and checks on the primary software. If the hyperbole is measured regularly with different K from the project but compatible with the scheme, we stop and move on to the next step

- optimization of the optical schema with the new measured conic constant.

- construction of the secondary function of the parameters of the optimized optical scheme.

- tests / measurements obtained on the secondary and further verification of compatibility. Optimization of the optical scheme resulting image with the actual values for both of the mirrors .

- calculation of the final parameters ( in function of the manufactured mirrors ) for the design of the telescope structure.

CAR-BUILDING: Is’ EASIER

In general, the optical tolerances of a system Rc are almost equal to zero. The simplification we're going to get with respect to a processing “strict” in which both of the mirrors must be made with absolute precision with respect to the design parameters is therefore this:

1 there is provided a primary and hyperbolic, if different from the project, and “plays” on the secondary parameters in order to adapt to it.

2- likewise, He realizes the secondary convex and, if different from the design values, and “plays” on mechanical parameters (back-focus, distance between the mirrors, focal overall ) up to find the suitable and functional configuration schema.

in this way, with a little’ of luck, It reverses the constructive approach, the scheme will be made to adapt to the mirrors and not vice versa.

Then, even if we can not accurately achieve the budgeted values, we will have the opportunity to change their configurations and find the relevant project for which the mirrors are “perfect” in their real parameters, a great advantage !

in the second part we will begin to go into the details of the above statements,we will see how to properly design our Ritchey-Chretien optical design format in the software and how to start “to play” with the possible configurations.

Stefanosky