We have seen in a previous article the general operation of the technique of strokes with sub-diameter. On that occasion, we examined the aspect relating to processing by identifying the zones or circular sectors in which the material removal takes place more or less effectively.

Let us now go into more detail on the effects that this process produces on the curvature of the conic that is being generated at the moment when we use the sub-diameter to make corrections in certain areas.

What in fact interesting to grattavetro is to know in advance as a mirror field will change its curvature as a function of a specific technique.

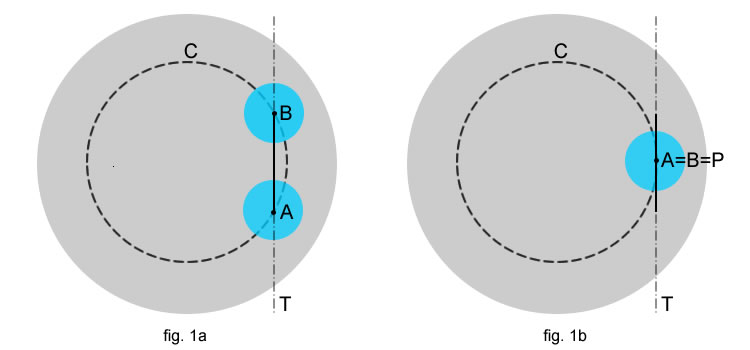

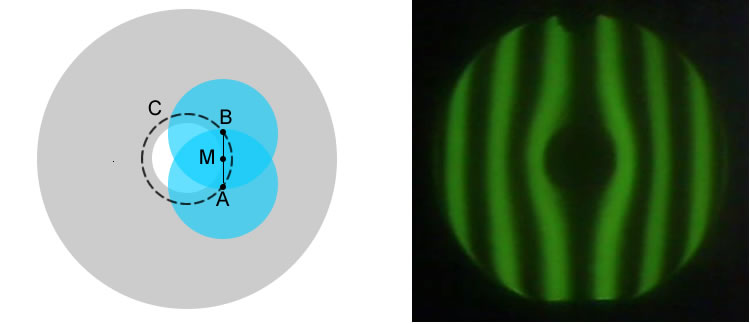

To do this we fix the first “degrees of freedom” processing ( fig 1a ), summarize ie in many ways and second directions and extensions such as the sub-tool it can be moved on the mirror.

- circular motion (-) relative to a diameter generated by the rotation operator ( or of the turntable )

- movement to and fro according to a secant T the circumference -

- extension of the stroke along the segment A-B the line T

- localized pressure at a given point P tool.

- constant tool rotation

As we will see all the points highlighted affect the final result, in other words, the variation of the curvature on the surface of the work is determined by the combination of these elements.

SIMPLIFIED APPROACH

For convenience of understanding, first we examine a particular case that will help us later to extend the results obtained in general form.

With reference to Figure 1b suppose to minimize the displacement of comings and goings A-B up almost to equate the two points A e B, What, however, achievable only by moving the rotation tool above the mirror on a rotating floor, we also consider the increasingly localized pressure at the center.

This simplification in which the straight line T becomes tangent to the circumference C and A = B, It takes us back to the case in the general aspects regarding the excavation with sub-diameter and allows us to make some important assessments starting with an aspect already examined:

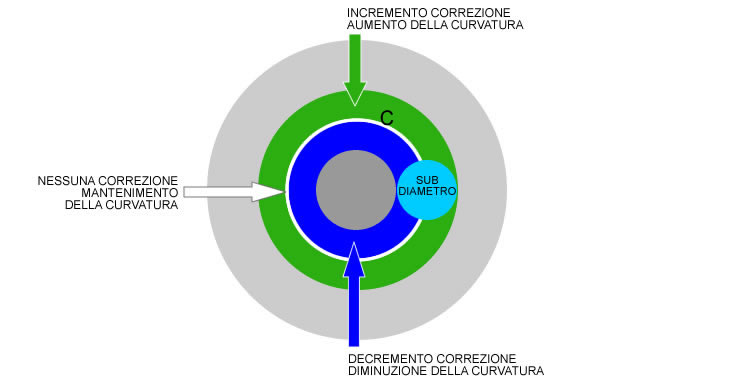

It will generate a circular crown with a depression at the center in which the removal of material will be maximum along the circumference passing through the tool center.

Thus generating a depression along the circumference and for an obvious consideration of the continuity of the figure generated, that we will:

- the outer zone in this circumference will increase its curvature, while the inner one the decrease accordingly

- The loop circumference C for the tool center unchanged will retain its curvature .

- the overall extension of the correct areas is equal to the extension of the sub-diameter ( in this case that A,B=0 )

Fig. 2 – variations of curvature with non-extended strokes.

The increase of the curvature in a zone indicates that the correction to the radius of curvature will tend to decrease the value, in practice in this area the fire come “a bit’ before” compared to the starting fire, similarly in the opposite area the decrease of the curvature will tend to lengthen the fire, always compared to the values before the correction.

The maintenance of curvature on the circumference passing through the tool center, It does not mean that the focus remains unchanged, but only that the figure will retain the trend departure, for example, if it was a spherical zone, it will remain spherical , similarly if it was already present an increasing tendency of the curvature, to find ourselves almost unchanged after the work session.

Then, in cases where the run-and-fro of the sub-diameter assumes very small values ( 1/8 or less sub-d, forward and backward similarly) we can definitely bring our work to this extreme case and take a circle through the center of the sub-reference tool.

GENERAL APPEARANCE OF CORRECTIONS WITH SUB-DIAMETER

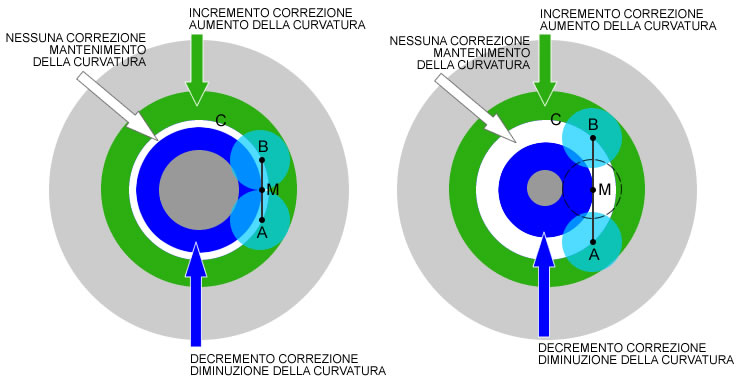

If we introduce the extension of the broad movement of “and fro”, we derive the tool center intercepts the circumference - in two places A e B, while call M the midpoint of FROM .

Fig. 3 – Variations of the curvature with application of extended racing.

Extending the reasoning for points A e B coincident, it turns out that the tool center, area in which the excavation has the greatest effectiveness, It will not move along a circumference but along a circular sector , in which the outer circumference limit is detected by the rotation of the outer between the points A and B ( if they are symmetrical circumferences coincide ) , while the inner circumference is determined by the rotation of the point M.

The consequence of this variation is the largest area of the sector in which the processing maintains the original curvature, while the areas to over- and under suffer an offset correction and a reduction of area by reason of this extension, In fact, the different positions of the points A e B refer to the same starting circumference - the case of coincident points.

The retention of the curvature is, however, an effect “temporary”, valid in the case of fairly short sessions, with the increase of the processing time on the same sector is that of the tendency “level” the intermediate zone.

We will see more depth when it is most convenient to use short or long runs, for now we can say that the move away from the tangent of the base circle, or in other words, more we lengthen the races we move towards the center, more we tend to generate a spherical sector between the zones subject to correction.

SPECIAL CASES

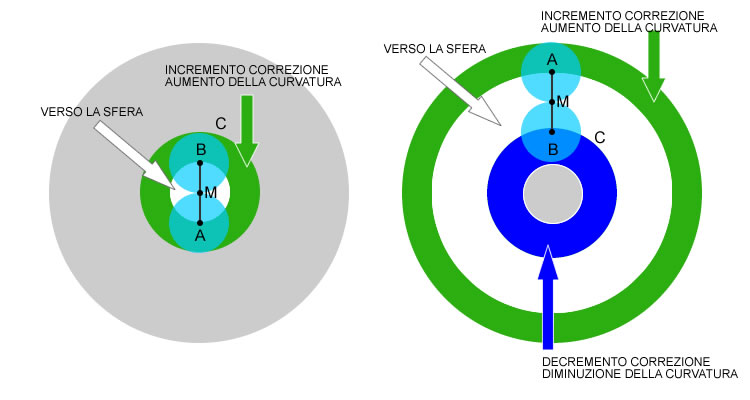

In general, the most effective processing is the one that acts “the side” to the reference circumference, this does not mean that they can also be carried out central races or even the center of the center.

In these cases, the type of processing together with the constant rotation leads to making “stable” the intermediate zone between the correction areas in making spherical. In the event of a “pure” center on center with suB-diameter will be missing in the area under-correction which will be completely absorbed by the passage of the tool center.

Fig. 4 – Examples of central races.

A PRACTICAL EXAMPLE

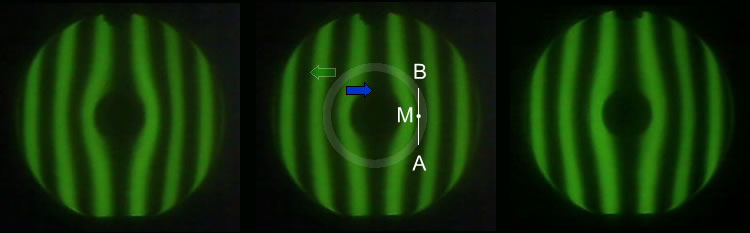

In this example taken from the processing of the primary Cassegrain, we consider this figure resulting from the Ronchi test, after the action of the sub-diameter in-hole close to the edge area.

Fig. 5 – deepening technique of the center of perforated mirror.

This processing was performed with M tangent to the hole, right to create the central depth without a curvature area descending, namely a raised edge on the hole, also seen that it is not possible to completely switch over the hole with the tool, to be able to make a stroke the center must always rest on the surface.

The “hole” Central then had to be connected with the outer zones to continue to build the parabolic.

The technique adopted was to move along an outer circumference and identify the extreme points of the races on “edge” the sudden change of curvature, per “enlarge” The outer bands ( increase of the curvature – green Arrow, fig 6) e “tighten” what internal ( decrease of the curvature – blue arrow, fig. 6 ) to the reference circumference:

This sequence of images before and after a session of 30 minutes with a sub-diameter 120 mm.

Fig. 6 – from the left: Figure departure, technique applied, resulting figure.

As you can see, the central hole is “spread” in a wider area. Continuing the action by moving to step outwardly to locate in the same manner the circular areas on which to apply the correction, the entire surface is possible to connect, to reach the desired figure.

CONCLUSIONS

two important considerations which constitute the fundamental preconditions for the use of sub-diameter:

- Is’ always possible to increase or decrease the curvature of a single zone .

- The sub-diameter allows us to intervene in both coarse so that with surgical precision on the surface and to modify the trend as a function of the tool magnitude of the applied pressure and the processing time.

we will see in subsequent articles that it is possible starting from these fundamental , get to build any type of conical surface you want to accomplish for our mirror.

Bartolomei Mirco

massimar

Giulio TiberinI

massimar

Bartolomei Mirco

massimar

Search topics

Giulio TiberinI

Search topics

Massimo Marconi

Search topics

Massimo Marconi

Search topics