Forum Replies Created

-

AuthorPosts

-

Hi Stefano

In my opinion the tool you could leave him without the grooves at least until use of the grain 400.

In fact, with the biggest trouble you just dig without worry that much to create scratches on the surface. I used a tool similar drowning in the plaster of the pieces of glass with a thickness of 20 mm and for the excavation has gone very well. Since the grain 400 in my opinion it is good that the part plaster does not go directly in contact with the mirror as though aligned more tender principle of the glass can still create micro grooves (perhaps due to the fact that if the cleaning is not perfect when changing abrasive few grains may remain stuck in the plaster?) quite boring that would force you to go back to the previous grain. Furthermore it agrees perfectly grind the edges of each tile to prevent detaching of the micro chips that would be deleterious.

However overall the tool you've done seems well built, I believe without a doubt the best of the diamond blade that even if he ran as fast to reach the desired arrow, He would still forced to build a tool adapted to the excavation made in order to then continue with the finer grits.

In any case, I know that I follow with interest your job, because personally I am currently unable to continue the work of my 300 mm. In my garage now it is not too well and to give you an idea of why I attach a photo .......

Ciao Uraniborg.

Dove sei riusci a trovare il vetro da 37 mm e a che cifre?

In bocca al lupo per la magnifica avventura che ti accingi a vivere!

Hi Stefano, A warm welcome also from me.

You are about to start a wonderful adventure that will bring you many headaches but also incredible satisfactions. I'm not so experienced that I can give you advice, the only mirror I have worked on so far is a 200mm mirror that I am completing with a multilayer Dobsonian structure and aluminum tubes.

The only thing I feel like telling you is to hold out when difficulties inevitably arise. Eventually you will see the solution is always found.

Good luck

GiuseppeThe engine ½ hp in my opinion is more than enough. Keep in mind that my engine washing machine if I remember correctly a rated power of approximately 450 watt, then more power but very similar to yours, I just do food through a varlight (your that I know can not do it). This allows me to get 30 revolutions / minute of the plate that, having regard to the mechanical reductions, They should be approximately 3000 rev / min motor, then approximately 1/3 the number of rounds that are obtained by feeding in 220 volts. This should correspond to approximately one hundred watts actually paid, therefore much lower than the power supplied by your. Honestly, I never bothered to make a measurement, as is indeed feasible with a simple tester. As I got to say, when the pot turns around 30 giri / min, They are able to block the rotation with one hand. This, however, I consider it a virtue not a flaw. If not, just think what would happen if the other hand we would end up randomly brrrr ......

.

.

As for the polishing I always I make machine-although with some difficulty to be able to get a decent ball, and the 200 mm are also able to parabolizzarlo.

Anyhow, after polishing with the turntable, nobody will prevent you to switch to manual processing if you were in difficulties in the sphere before and then the parable.hello Uraniborg.

About thirty revolutions per minute is in fact the rotation speed that most use. In practice only during the roughing step to increase the speed of one revolution per second and even more by placing the mirror above and passed with a very decentralized in the past as "chordal" of handwork. This allows me to dig very quickly, but just as in manual processing the ball you get is not very good. Once you get close to the desired depth, to regularize the past alternately 1/3 center with the center of the mirror over to past the center of the center long almost to ½ placing the mirror under. Usually the excavation using the I make the grain 80 and the surface with regularization 120 and with 220. Step to the next grits always alternating mirror above and below only if the spherometer tells me that the surface is sufficiently correct. With regard to the movement of the arm, the speed is approximately one pass per second. I get small variations fueling the engine with voltages ranging from 9 volts to just under 20 volts (I do not remember the exact value).

Reading these lines you'll think of mirrors I worked there so many and indeed it is. As soon as I started this adventure with my colleagues I have blank various mirrors or should I call them pieces of glass, just to understand the functioning of the whole. The first pieces were pretty thin glass max 15 mm circa. Then we were able to procure from the glass 20 mm from which a disc we obtained from 20 cm in diameter, and this was the first and only time that we brought to parabolizzazione. I am currently working on a 300 mm.

So if you find yourself with this engine 30 revolutions per minute of which specify neither power supply they ( in many volts funzuina? you brush? He works for DC or AC ...) you can build yourself actually think of a rotating plane. I'm sure you will be of great help but remember that at least so far have not been able to find a configuration that in the process of polishing stably bring the ball.hello BART

Excuse me but I was not aware of your surgery.

Thanks to you for the compliments.

In fact, the wiper motor is what in the various processes is slightly undersized but in the vast majority of situations if the weel.

The real problems stem from being able to understand what adjustments taken in the various situations that arise.

As I mentioned earlier a big hand me from the program POLSIM, but I assure you that often is not enough. Anyway I'm happy to have it built and have it available for my experiments.

hello Uraniborg, thanks for the compliments.

Even in the future, if you were to type needed my help or suggestions you have only to ask.

Hi everyone.

What a nasty surprise!!!

I followed with great interest your job because I too had thought of working a lightened glass but thanks to the ribs proves still very hard.

I'm so sorry and I understand well what will be your state of mind.

But I am almost certain that we passed the discomfort riproverai!

Hail

Giuseppehello Frank

Vorrei associarmi anche io al benvenuto che ti ha accolto qui nella comunità del GRATTAVETRO, quindi visto che anche tu stai aspettando che mi decida a pubblicare qualcosa sulla macchina per lavorare gli specchi, posso dirti che sto ultimando la raccolta del materiale necessario e spero al più presto di pubblicarlo sul sito. Vi avverto subito però che le vostre aspettative in merito mi sembrano quanto meno esagerate. Hai scritto di essere rimasto impressionato dai risultati che ho ottenuto sul 200 mm e devo dire che anche io ho strabuzzato gli occhi le prime volte che li ho visti apparire sul PC. Detto questo vorrei provare a chiarire alcuni punti:

until ) Sono certo che non appena vedrete foto e filmati della macchina vi renderete che si tratta di un prodotto molto “artigianale”. Ho avuto modo di vedere il tuo pantografo sul sito della Northek che al contrario ha un aspetto molto professionale.

b) Ammesso e non concesso che quei dati siano veritieri (attualmente sto costruendo la struttura del Dobson che lo accoglierà e che spero mi darà finalmente una risposta abbastanza sicura a riguardo) c’è da chiedersi se effettivamente il merito sia della macchina. Inizialmente avevo provato a parabolizzare a mano ma dopo pochi minuti di lavoro mi sono sempre ritrovato oltre la parabola. Quindi dopo essere ritornato per l’ennesima volta alla sfera ho voluto provare a parabolizzare con la macchina. Ho apportato una piccola modifica alla stessa che mi permette di allungare o accorciare il braccio oscillante mentre lo stesso è in movimento e ho iniziato il lavoro ponendo lo specchio, che stava sopra, con il centro quasi sul bordo dell’utensile. Quindi mentre la macchina era in funzione ho accorciato il braccio fino a riportare il centro dello specchio sul centro dell’utensile, quindi ho fatto l’operazione inversa. Tutto ciò per due o tre volte. Alla fine ho controllato lo specchio con Ronchi e poi con Foucault ed risultati sono quelli che avete visto. Merito della macchina? Bravura mia? Oppure semplice botta di c…? Io al momento propendo per la terza soluzione.

C) La macchina funziona alla grande per la sbozzatura e per l’affinamento della superficie con gli abrasivi fino al 1200. La qualità della superficie che si ottiene è solitamente molto buona, la satinatura è finissima e uniforme e lo sferometro dotato di un comparatore centesimale con quadrante da orologio non mostra alcun movimento della lancetta muovendo lo sferometro su tutta la superficie. I problemi spesso sorgono con la lucidatura, problemi che io al momento attribuisco alla patina di pece. Alla fine comunque riesco ad ottenere una superficie brillante e senza microcrateri o rugosità, si lascia lavorare la macchina fino a che si è soddisfatti. Basta aver l’accortezza di far lavorare l’utensile senza grossi pesi, soprattutto a fine lucidatura, che aumentando la pressione sulla superficie di contatto generano problemi di qualità. Discorso diverso per quel che riguarda il raggiungimento della sfera. In alcune occasioni sembra la cosa più semplice del mondo in altre un traguardo impossibile da raggiungere. Mi ripeto al momento attribuisco il tutto alla durezza della pece ed al suo adattamento, but I could be wrong. Per inciso la patina del 200 mm era fatta con pece GUGOLZ 55 e non appena le temperature sono salite intorno ai 16°C ha iniziato a lavorare molto bene mentre con il 300 mm sto usando una patina con pece GUGOLZ 64 che risulta ancora troppo dura per le temperature attuali (siamo intorno ai 18°C)

O) La macchina ha il grande pregio di non stancarsi anche dopo ore ed ore continuative di lavoro ma detto questo bisogna sapere che prima di capire anche solo a grandi linee come reagisce alle regolazioni talvolta ci si spazientisce parecchio. Ad ogni modo ora che l’ho costruita sono ben contento di averla ma non la consiglierei a coloro che non hanno alcuna esperienza nella lavorazione di uno specchio.Un saluto a tutti e spero a presto

Giuseppe MuraEccomi di nuovo fra voi

Purtroppo come già ho avuto modo di dire in questi giorni sono piuttosto incasinato con il lavoro. A ciò si è aggiunto il fatto che qualche giorno fa mi è scaduta la patente e non vi dico cosa sto passando per cercare di farmela rinnovare. Continuano a farmi girare da un luogo all’altro per richiedere certificati medici ma di rinnovo ancora non se ne parla. Mi sento preso per i fondelli e sono inc…..to nero.

All that said, , qualche sera fa sono riuscito a fare alcune foto allo specchio attraverso il reticolo di Ronchi. Purtroppo come qualità non sono troppo buone. Le ho fatte con il cellulare ed il reticolo che uso è stato ottenuto mediante stampa di 5 lines per mm. su un foglio lucido con stampante laser. Il reticolo è stato poi sistemato su un telaietto per diapositive. Il tutto è inserito sull’apparato di Foucault in modo da intercettare prima la luce di un diodo led diretta verso lo specchio e poi il fascio di ritorno riflesso dallo specchio. In questo modo evito di dover porre una fenditura davanti al led, infatti è il reticolo stesso a fare da fenditura. Una fenditura è posta invece davanti ad un altro led che uso quando effettuo le misure con il metodo di Foucault. E’ un sistema che trovo più pratico e che mi sembra funzioni bene perlomeno nelle osservazioni dirette. In ogni caso io allego le foto voi ditemi cosa ne pensate e consigliatemi pure sul da farsi per farle un pochino migliori.

A Giulio vorrei dire che i complimenti fanno sempre ma ti assicuro che si amo ben lontani dal livello di certi personaggi. Figuriamoci, Richard Feynmann (che per inciso è uno degli scienziati del passato recente che più stimo ed ammiro) era uno che notoriamente amava stare a contatto con i propri studenti non limitandosi ad impartire loro le proprie lezioni per poi sparire dalla loro vista. Con loro ci parlava ci discuteva e ci stava il più possibile insieme. Ecco questo è forse l’unico punto di contatto. Per il resto io sono come un aliscafo che plana sull’acqua, Lui era un jet che volava a quote stratosferiche. Non scherziamo ragazzi!!!

Per quanto riguarda il piano rotante prometto che non appena possibile cercherò di preparare un pochino di materiale per mostrarvi come lo ho realizzato e come lo uso.

Per il momento accontentiamoci di farci due chiacchiere e di scambiarci opinioni sulla nostra passione comune.https://s29.postimg.cc/m3p7yqh8n/intrafocale_1.jpg

https://s29.postimg.cc/gq1eum8br/intrafocale_2.jpg

https://s8.postimg.cc/8q4fbhx79/intrafocale_3.jpg

https://s27.postimg.cc/7ff8kl02r/extrafocale_1.jpg

https://s17.postimg.cc/rjhvqxnb3/extrafocale_2.jpg

https://s11.postimg.cc/rngslvccz/extrafocale_3.jpg

https://s30.postimg.cc/5bcxheugh/extrafocale_4.jpgUn saluto a te Mirco e un ringraziamento per la calorosa accoglienza.

Per quanto riguarda le foto dello specchio visto attraverso il reticolo di Ronchi devo chiederti di pazientare un po’ in quanto lo specchio è montato su un tubo in PVC per cui dovrò trovare il tempo per smontarlo e provare a fare le foto. Al momento sono piuttosto incasinato con il lavoro e tempo da dedicare al resto non ne ho tantissimo, ma quanto prima cercherò di accontentarti.

Per il momento posso solo dirti che il test di Ronchi mi è stato molto utile prima per raggiungere la sfera e poi durante la fase di parabolizzazione. Solo alla fine sono passato alle misure con Foucault, quando confrontando ciò che osservavo attraverso il reticolo con le figure mostrate dal programma Ronchi for windows 2.0 mi sono reso conto di essere vicino ad una buona parabola, ed in effetti le misure mi hanno confermato quanto mostrato dal Ronchi.

Volevo anche ringraziare Giulio per quanto ha scritto sull’alluminatura e sulle ditte che la eseguono.

La mia domanda però riguardava eventuali preferenze fra le due ditte che peraltro già conoscevo almeno di nome.

Hello everybodyhello Giulio

I do not hide that your compliments and those of Massimo make me extremely happy and after an infinite number of hours spent trying and trying again just to be able to get a decent sphere now all this fills me with pride. I do not hide that your compliments and those of Massimo make me extremely happy and after an infinite number of hours spent trying and trying again just to be able to get a decent sphere now all this fills me with pride. I do not hide that your compliments and those of Massimo make me extremely happy and after an infinite number of hours spent trying and trying again just to be able to get a decent sphere now all this fills me with pride.

I do not hide that your compliments and those of Massimo make me extremely happy and after an infinite number of hours spent trying and trying again just to be able to get a decent sphere now all this fills me with pride, we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise. we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise. we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise. we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise, we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise, we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise. we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise. we wait to ring the bells because as you rightly said the Foucault test is quite subjective and it will be better to carry out other tests including a star test before defining it as wonderful or otherwise 19 mm. Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one. Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one. Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one. Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one. Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one, Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one, Well it happened the bit as it dug and widened slightly so we have that the lower face is very little bigger than the upper one.

Hi everyoneThanks Massimo

Judging by the test, the quality is excellent, Judging by the test, the quality is excellent, Judging by the test, the quality is excellent. The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted.

The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted.

The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted, The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted, The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted. The only thing to point out is the fact that I started from a good sphere and with the tool perfectly adapted.

Ciaobut there are many other similar ones

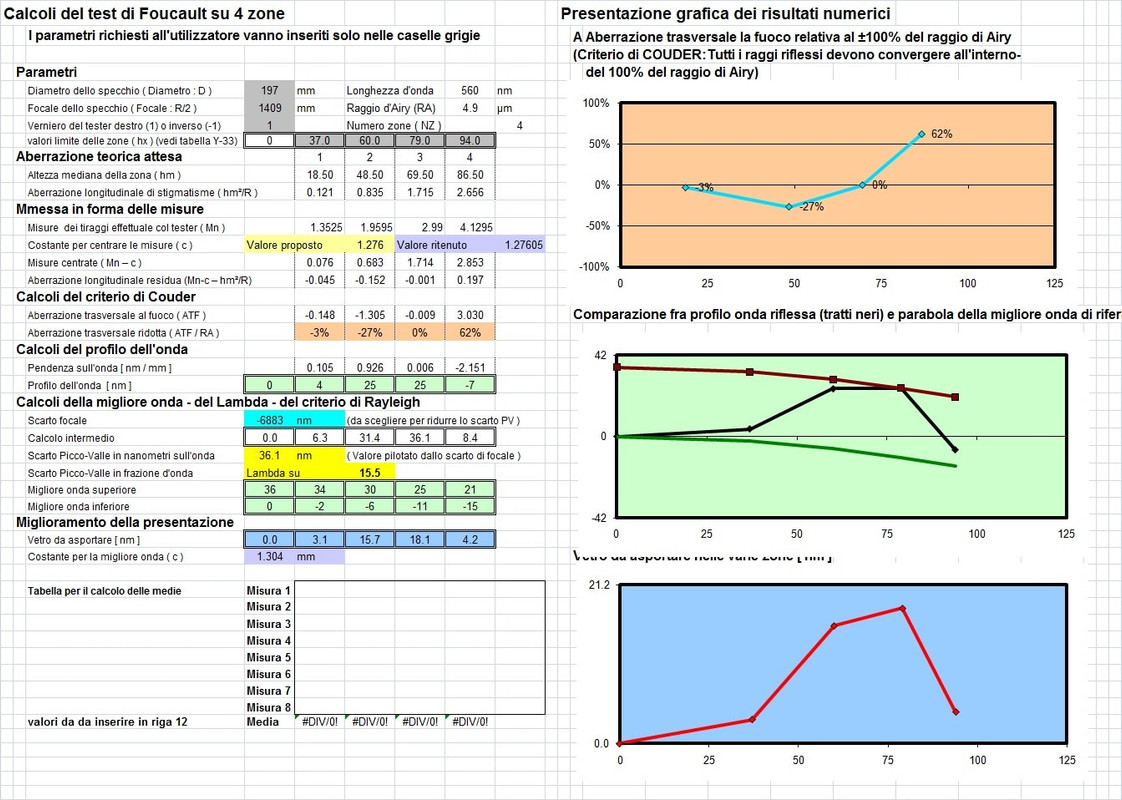

As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from 200 mm.

As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from. As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from.

As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from.

As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from.

As previously said I try to publish the data and the graphs of the spreadsheet regarding the mirror from. The telescope was placed on a laboratory bench. 70 The telescope was placed on a laboratory bench., The telescope was placed on a laboratory bench. 20 mm (70 magnifications) The telescope was placed on a laboratory bench. 12 mm (116 magnifications).

The telescope was placed on a laboratory bench., The telescope was placed on a laboratory bench., The telescope was placed on a laboratory bench., The telescope was placed on a laboratory bench..

The telescope was placed on a laboratory bench. 4 mm (350 X) The telescope was placed on a laboratory bench., to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror, to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror.

to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror.

to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror.

to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror, to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror.

to the inaccurate alignment of the optics or if it was due to the processing limit of the mirror

Hello everybody

You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far.

You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far. You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far. You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far. You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far. You have to excuse me but given my unfamiliarity with the forums I find it difficult to keep faith with what was promised, that is to report on the work done so far -

AuthorPosts