Forum Replies Created

-

AuthorPosts

-

hello Henry,

thanks for the answers…

but not being Pyrex brings problems to the project success?

There are pros about it?The guy e-bay is just in Cremona…I know that is your same supplier

cmq crepi the wolf

scratching scratching….

So this week I added another three chamfer sessions coming to an arrow 2,7 mm (obviously only the central part) while on the edges I ate about 1 mm for a total of 10,5 hour!

I must say that the work is really hard grattavetro…I did not think that the glass was so hard to consume

…

…I need an opinion on the glass that I'm working…

The guy from whom I bought told me that the glass had been aged for several years, It means that the glass is much stronger?

Being a Pyrex glass you could also heat up to high temperatures without suffering? (80/90 degrees)

hello Giulio,

the video that places me is very interesting but perhaps not as much to do with my rotary table running around 150-200 rpm!(even if I could make a change)That's why I thought of using the sandpaper silicon carbide(use the powder would have been a bad idea given the high speed of the plane),even if it costs a bit more than the powder purchased from Gemmarum :negative:, but it does not matter…what matters for me is to get to the goal…although as you say you will take me more time.

The cross that is made to see in that video I had already planned to finish the job and make the glass a perfect sphere…Then I show you how!!

thank you so much!

@Maximum

Arguably the roughly glass is not have a point more dug in the middle than the sides…I'll try to improve in the coming sessions

For sfera no problem…I think I can obtain it just needs time!

@Giulio

I use mainly of the rotating plane using a small tool but also to alternating I passed manual vertical Moving on to W…

here I am,

Update a little post…therefore, with regard to the mahk90 (I apologize to the forum for mistyped an abbreviation for the telescope

)I meant a Newton 130 mm then that is the one mentioned at the beginning of post…I was wondering if you could reuse seen that the mirror is flat even though I was uncertain in sizes(I see too small)…still well I decide later…Meanwhile, I refer to the link you passed me to recover a possible plane mirror

)I meant a Newton 130 mm then that is the one mentioned at the beginning of post…I was wondering if you could reuse seen that the mirror is flat even though I was uncertain in sizes(I see too small)…still well I decide later…Meanwhile, I refer to the link you passed me to recover a possible plane mirror

thanks Giulio

thanks Giulio

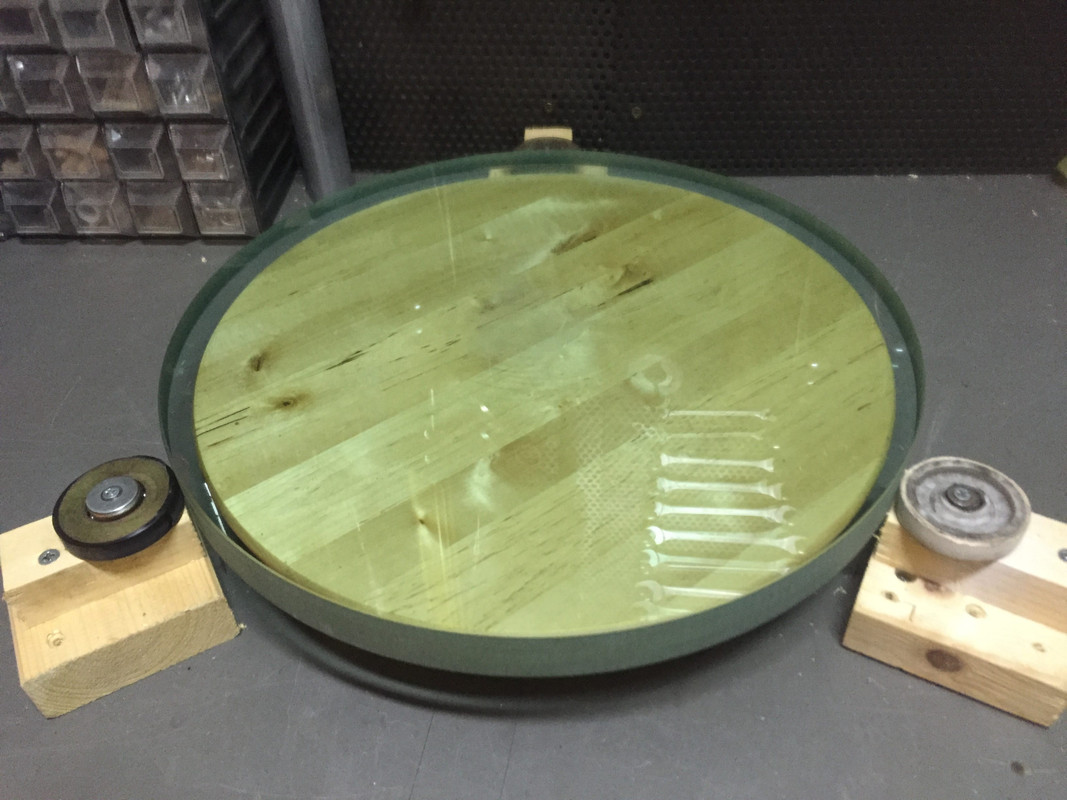

Meanwhile, it shows you the progress of the work of scratch scratch…

these days I managed to recover three bevel sessions to around 1,4 Arrow mm and about 5 hours of abrasion….ask for more experienced if more or less back with the drawn arrow Rates

I seem to dig very slowly(maybe it's just me

I seem to dig very slowly(maybe it's just me  )

)

For now I'm using the grain 40 to work, however, they notice the big scratches on the glass….I hope to smooth them again later with the finer grits

I wondered as part of the arrow using the 40 grit…I had thought up to 5-6mm(Correct me if I'm wrong )

)here is the glass worked with about 1.4mm Arrow…

measurement of the arrow I'm running with a homemade spherometer…I was inspired by the place of Mirko

See you soon!!

The dual configuration a bit attracts me…

Apart from the fact that so the arrow would be reduced by a lot…0,641 cm, About two millimeters less to dig and on the other hand it would immediately provide a system already ready you can use (and I can not wait to try the mirror 41

and on the other hand it would immediately provide a system already ready you can use (and I can not wait to try the mirror 41  )

)

But if I choose this route should drill the pipe in two places and then prepare it for both Newton and for the right Cassegrain?

As far as I could diagonal plan to use that of the current Newton?(Mak 90)Meanwhile, thanks for the idea…surely I will assess your advice ammodo

Tomorrow I give start the ball rolling…I begin to work the glass seen mm to dig!!

See you soon

ciao,

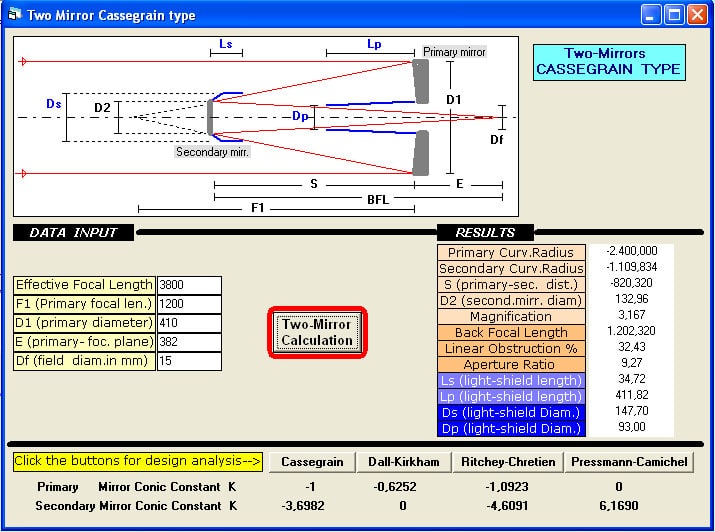

So for I again arrow wrong to transcribe…I expressed the extent to mm in the project(I'm 0,856 cm)…I made the same mistake the starting post

then take off the glass I have a lot '…

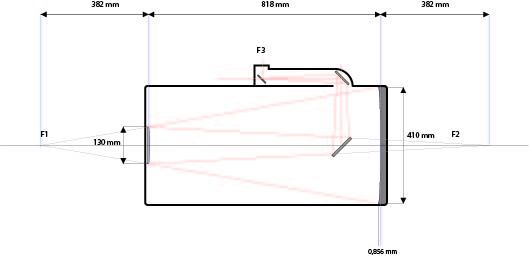

for the size of the tube maybe in graphic design is unclear cmq I will take it to the end now interests me realize optical (the hardest part)…the other problems I solve them by road

I like to go by degree…

I like to go by degree…

regarding the diagonals if I move to the secondary I find a F3 much longer to accommodate…I inserted to obtain a high final focal length and also to straighten the image(correct me if I'm wrong)….In fact, I aimed at 3600 by calculations made with ATMOS and I managed to get 3800

What alternative solutions could be observed instead of the Cassegrain?

It would be the easiest solution?Thanks!

p.s.

ho 43 years!

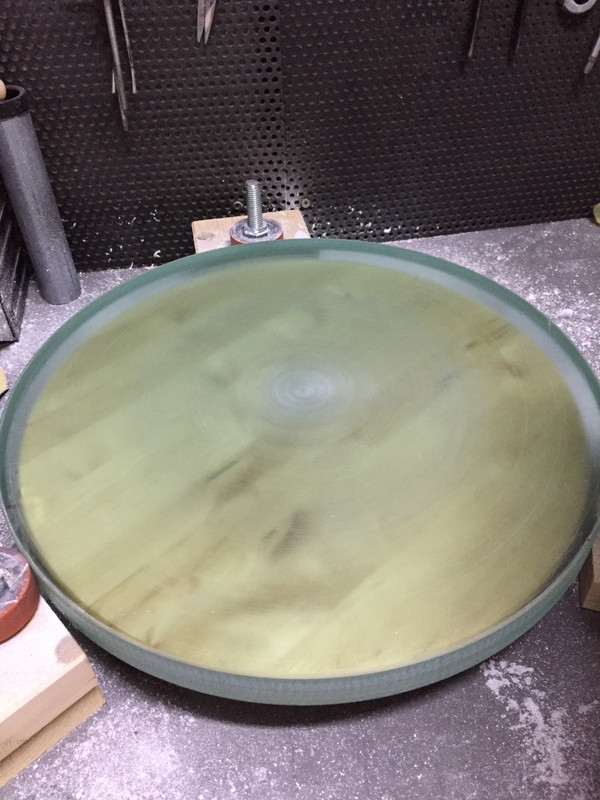

a better picture of my piece of glass placed on the rotating stage that will facilitate my work

…I have completed these days,I owe it to test with the glass moving, of course I have to connect the belt he will turn…begin on Monday, the first scratch

…I have completed these days,I owe it to test with the glass moving, of course I have to connect the belt he will turn…begin on Monday, the first scratch  we'll see how everything evolves!!

we'll see how everything evolves!!

but here my initial project developed with a vector graphics program

Finally place also elaborated project with ATMOS with different values from which roughly coincide with the actual project

So I had already tried as you say….In fact, I had loaded the direct connection, however, there must be a problem as visualized only the title dell'img….then try again

Hi Massimo,

I must say that I only had a blow of c..o

I found a guy on eBay who sold two 90 Euros and I have cornered me one

based on the information you gave me I will try to set the values then update for some advice , I had already tried some rough calculations with ATMOS but do not coincide with my project in fact the secondary mirror would be completely different in size…

, I had already tried some rough calculations with ATMOS but do not coincide with my project in fact the secondary mirror would be completely different in size…

thanks for now I update

Hi guys,

I update you on the situation…I finally found the glass to be processed (41 cm x 3)

I would say that next week I should be operational, I start the first scratch ,we hope well

,we hope well

I tried to use ATMOS ricavarmi for various values of the telescope…

choosing the Cassegrain setup I find some unclear rumors

The first speaks of “Effective focal length” It means the definitive focal you want to achieve?

The last entry “Df in mm” what does it represent?

I also want to load some jpg project I must use of external sites?!thank you!

Everything ok Massimo no need to apologize…The rookie is me!!

I fully what they say Giulio and Mirco…for me it will be almost impossible to complete the company but I want to try the same….I just hope not to disappoint!!As soon as I start the work will update….

See you soon and thanks for the info!!!

@Maximum

Thanks for the support!

I wanted also to tell you that I'm also following your post which by the way I thought it was a godsend…is just for my case!

I saw that in your project, please refer to the constant tapered both mirrors…I'll do it too?Is essential?

I also tried to calculate a focal might be able to get a project finished…3600 circa!

It might come as the length of the tube arrives at about 85 cm?!

As soon as I can I'll post also my project

@Giulio

I trust in you all!!

Hi guys,

First thanks for the replies…

I already knew the company to realize this mirror entailed huge effort and experience…why I still decided to go ahead…@Giulio

That video you posted I've already watched several times…precisely why I decided to start the company although it will be very difficult…especially for the arrow 8,5 mm to dig😫😫😫

As for the tile so I can feel comfortable…just drop me at work to procure immediately!I am confident of the entire board support…

As soon as possible to update the situation by opening a new post!See you soon and thanks for the advice

Luca -

AuthorPosts