Forum Replies Created

-

AuthorPosts

-

Ok Giulio I will as soon as possible to buy a small microscope

thanks a lot!!

hello Giulio!

Thanks for the quick response!

In my case I am making use of a sub-diameter to work on the ball, so I have not the possibility to reverse the tool with the mirror to correct the height of the arrow…alternative?

I do not know if your guides also speak of working with sub-diameter however, will give him a look tonight so maybe I will draw some solution to avoid possible errors!

To quantify the depth of the scratch I have available a 10x lens…you believe is enough?

Happy New Year to all the forums!

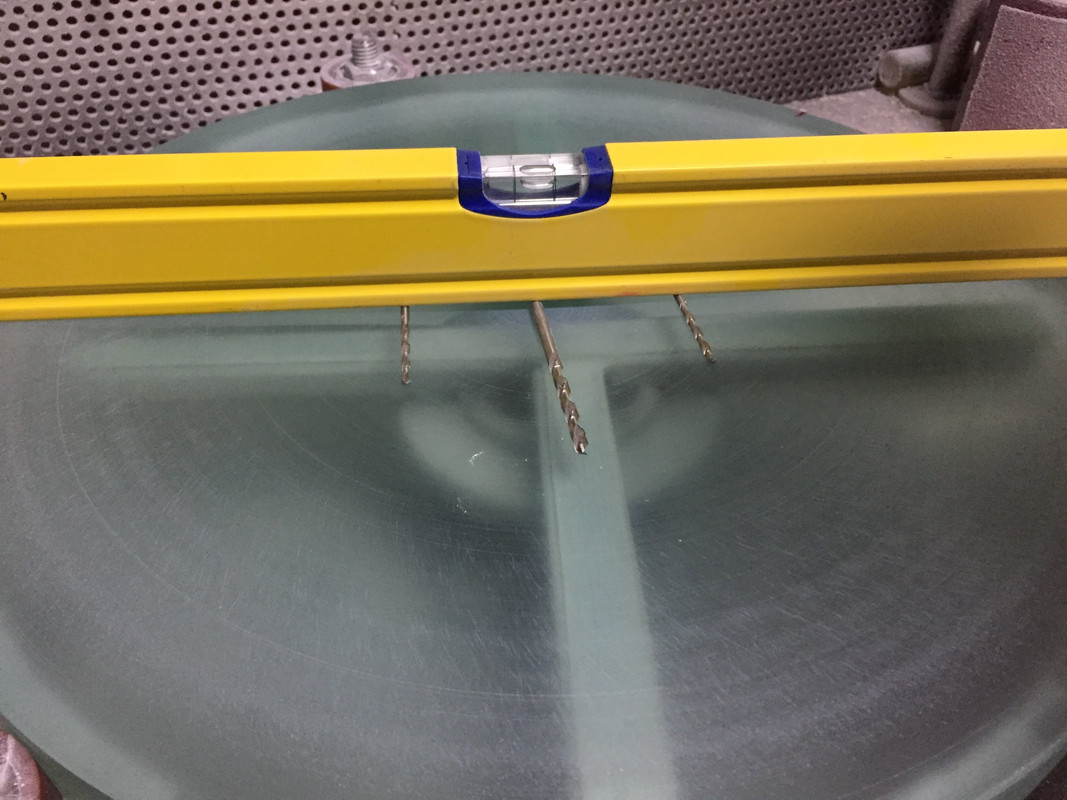

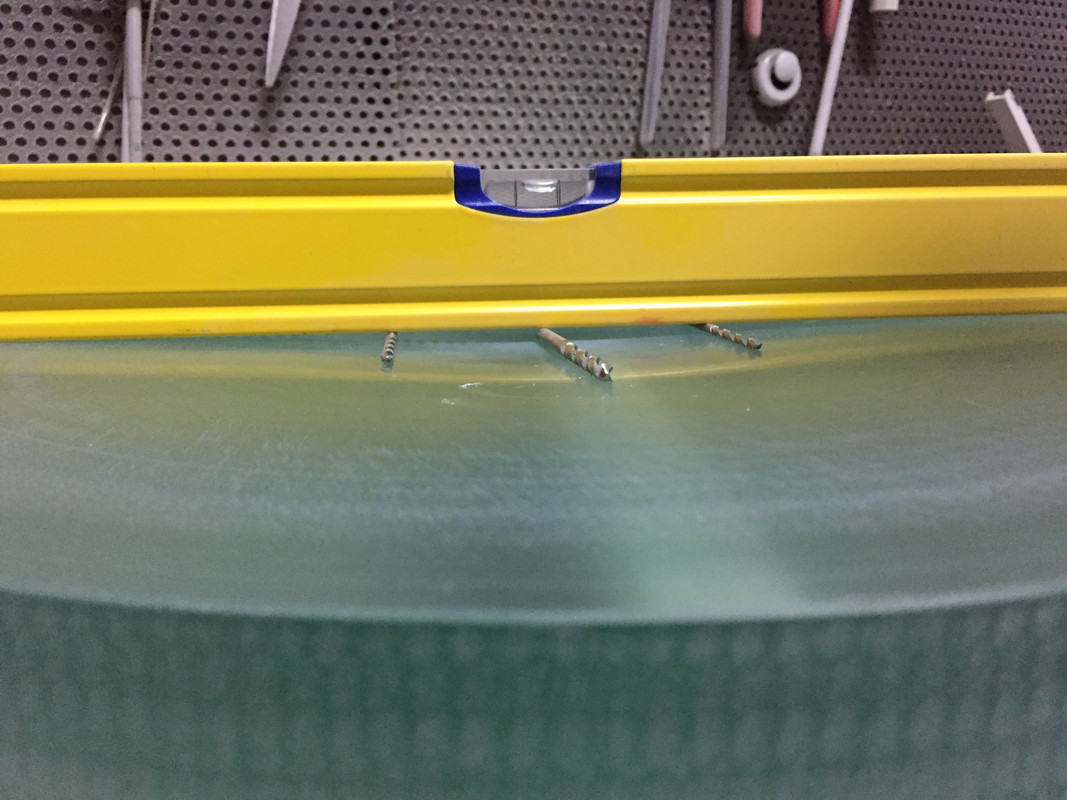

Here I am working to update my mirror after about three months reached the desired height or nearly…I still miss 1-2 tenths to end the spherical part.

I have performed a test for the curvature radius of the control and measurement roughly corresponds.

But I find a problem I have to solve, it concerns 3-4 scratches that do not seem deep, probably fall in the tenth of a millimeter or maybe less I could not say exactly!

I am currently working with the grain 320, I do not know if you go back to 150 remove the scratches and then return with the finer grits…or continue so.

The sooner ronchi execute a test to check if the mirror is truly spherical or if it presents the possible defects to be corrected.

If you exceed the height of the arrow established can be remedied?

Any advice is welcome!!

Thank you!

Merry Christmas from me to all the forums

See you soon

hello Giulio,

definitely roughing and working until the end of a mirror of this size there would be many more pros using a hand tool diameter…

To get close as possible to the shape of a sphere'm trying to keep controlled the height of the arc in all its points with a distance of about 1 cm from each other…since now the excavation that I have generated much reflects the shape of an arc…almost certainly I will have some areas to be roughed at the end but I have to wait for the verification of a first Ronchi…

Now if i ran a Ronchi test surely would find a central hole a diameter cm…this is the only fault I warn passing his hand on the mirror…(probably for now I'm wrong ) however, it does not seem a big deal,I correct him along the way so I still miss 1,2 mm for the final arrow…

) however, it does not seem a big deal,I correct him along the way so I still miss 1,2 mm for the final arrow…

They are much more concerned about running into other problems…(one case : astigmatism )

)As soon as I can execute the test…I'm very curious!

We hope that you have not made a mess

O.T.

Have any of you used the IR filters to observe the sky during the day??thank you!!

Perfect…good advice

The table you posted I will definitely comfortable…I have available a 10x lens that should be enough to identify the most profound signs

Thank you

Unfortunately in my case I'm using just the sub-diameter tools…then I will surely have some surprises to be corrected…

we will soon see

we will soon see

Ma 5 tenths with 60 suffice to fix the scratches of grit 40?!

Thanks Giulio

Well….It will mean that wait that the surface is quite smooth and then mention a first test ronchi…

Thank you!!

After about three weeks we take stock of the situation…

After totaled 20 hours of work I am about 1,5 mm from the final arrow…I dropped the grain 40 to proceed with the 60….I thought about doing 5 tenths then move on to 80 and then the subsequent.

I tried to give the mirror a similar shape as possible to a sphere and as a first draft seems ok…obviously more accurately I will verify the shape just performed the first ronchi (I think the grain 150 It is sufficient for a possible reading of the just rhonchi?!?:unsure: )

Any advice is welcome!!

Kill as many negative opinions…if I had known before I never published my idea…I had only to follow the forum in silence as a good spectator least I would not have gone through a mad visionary🙃😐😑😔😕

@Lelio

As I have explained in previous dialogues with Julius Maximus and Mirko I want to be my experience that is not to impress strength and finish well ... "I would like to” and I say I'd like to finish what I started…I hope so because I'm not used to put people…if this is successful I will be definitely satisfied 200% but since I have a good chance of failing in the end I will have lost only a little’ time for a hobby began recently and 200 euro spent on the purchase of raw materials(glass and abrasive)…you know that the time for grattavetro is not a problem ... the important thing for me is get to the end, finish what you started!As for the five-mirror system it is not safe to 100% who fail to complete, Massimo probably like I had mentioned earlier in the end we'll have to remove someone for optical management problems ... I'll see him after! For now my only problem is to finish the primary glass then pass to other ... considering I'm doing in his spare time ... I'm not killing fatigue, the rotary table I built precisely to avoid this ...

@Maximum

Thanks for your good wishes ... I need it!!

Mission Impossible!!

I finally settled on a F3

I want to complete the initial project even if it means to deal with a very difficult to achieve secondary convex and therefore much more time to lose

and therefore much more time to lose

It may seem strange but the hardest things fascinate me….it's stronger than me!

update a little post…

these days I reached the beauty of 4,6 mm arrow…now you start to see some results

In fact it is to assess both the aluminizing price shipping(risky says Giulio) or away from face…

Now we will see when the opportunity arises

Anyway thanks for the info!

hello Lelio!

I will try definitely!!

Thank you

Ok so in my opinion it is not a problem to worry about….so much 10 so much 15 min at the end temperature when it is in his work place him well…I was interested to know this!

Once this telescope I expect great satisfaction

Enrico from your post I read that you're in Carpi….We are close enough to me that I'm in Modena…I just wanted to know if you can advise me who's performing aluminum coating on the glass…I have not found a single one

Thanks for the clarification guys!

-

AuthorPosts