- This topic has 38 replies, 6 voices, and was last updated 4 years, 9 months ago by

skround.

-

AuthorPosts

-

3 June 2020 at 3:02 #11854

Hi Mirko, even if this topic is’ now old of 3 years I still want to write .

I find your approach very interesting and obviously’ a pity that it broke early.

Is’ one of those experiments that have the intuition and courage you need – and that I am a refreshing wind. And this applies regardless of the fact that with this method it is possible to obtain an adequate dimensional precision.

It reminds me a little’ -even if with different execution- the Hubble Optics approach.

Is’ a brilliant way to overcome the high cost of a standard approach through multiple use’ effective material. Is’ true that requires an oven but the potential is’ high.

Congratulations again – together with Marco e's 600mm f / 2.2’ one of the most projects’ interesting I've seen recently.

Regards,

Michele8 June 2020 at 17:53 #11863Hi Michele,

thank you!!

I also believe that this technique has potential, even though I have never been able to fully verify it. The drawback is that there is really a lot of work behind to obtain such a blank.

But the worm of blank lightweight always blends in my head, and sooner or later I hope to have time to try again.

Ciao

Mirco 13 June 2020 at 17:22 #11867

13 June 2020 at 17:22 #11867Sorry if I keep breaking – do you remember which descent profile you used?

You had checked the residual voltages with a polarized filter?

Is’ just to understand how the process can be strengthened – next time starting from a borosilicate slab I guess it will protect more from these tensions. It costs a little’ more’ but it would give more’ certainties of reaching the goal.

Last thing – you had thought of doing everything in one go or meniscus and structure? The failure could be partially considered in the geometry of the support parts. Then maybe you have access to the oven you used and it isn't’ a problem to make two passes.

For your info – maybe you already knew him:

http://rokoszoptical.yolasite.com/double-arch-mirror.php17 June 2020 at 1:13 #11874Hi Michele,

I had not set a precise descent curve and unfortunately we did not acquire the temperature data, simply once the high temperature maintenance is finished, we turned off the oven and let it cool down naturally all weekend. The following Monday we opened the oven and removed the blank.I had experimented with polarized light, slight tensions were noticed precisely at the edge of the mirror, but I was unable to quantify them. In hindsight it would have been appropriate to have him make an annealing cycle.

The residual stresses are proportional to the cooling rate and the thermal expansion coeff, therefore with the same cooling curve, in a pyrex blak one should be generated 1/3 tensions compared to one in calcium sodium. In fact, if I ever have to make another attempt, I would try to do it in pyrex.

Meniscus and structure had been generated in a single batch, and the pieces of the support structure in contact with the meniscus, they had been precut so as to take into account the curvature of the same.

I had already seen the link, but thanks for giving it back to me, I had missed it. The arrangement of the support ribs they had chosen didn't convince me at all, so I redesigned them according to other reasons and the result is that shown in the previous pages.

You already have something specific in mind for your project? do you have any idea?

See you soon

Ciao

Mirco17 June 2020 at 1:51 #11875For our project we are in full evaluation phase – our master of mirrors (which made three 500mm) e’ rather cautious and conservative – how is’ that it is. I am only afraid that this will lead him to not evaluate aspects that are common, they are extreme by the large diameter.

For example, he wants to do all-roughing up to parabolizzazione- with whole tool. There are 10kg of glass to be removed…do you! He never used the half tool’ instead I honestly have never seen anything different used for diameters above 400mm (more’ the name…).

Then:

there is a 53mm blank’ from Reginato ( or at least e’ to catalog) but they are 4000+ Euro. I honestly would have taken my tooth out once with a nice collection – the club though’ for now he doesn't hear us.Meniscus option (da 25mm) e’ the one more’ desirable – thermally even normal glass is not’ crazy but at that point with 800Euro there is also a disc of borosilicate.

But’ he never made a meniscus – aspe’, it is not’ vero, we tried a 120mm one which is’ it turned out well but we ran aground on a 400mm. Let's say he has no experience.So in parallel I am looking for borosilicate between China , Germany, UK, Canada etc…

That said’ , since he has the 'fregola’ or itchy hands since we kicked it off’ taken 2 25mm discs of normal glass and want to start working shortly. I know, I know. For now he is modifying the processing machine.

For me and’ extremely important that you gain confidence because’ in the end e’ he who will spend’ hours and hours on that piece of glass.

Even if he wants to make a 15mm arrow in a 25mm disc! At best we will end up with a tool already’ bent…24 June 2020 at 0:46 #11908Hi Michele

Machine roughing, I've always done it with a sub diameter tool, usually 60-70% of the diameter of the mirror and never with the tool at full diameter.

As for the choice of blank, just do two simple simulations to understand that a 25mm mirror is NOT rigid enough.

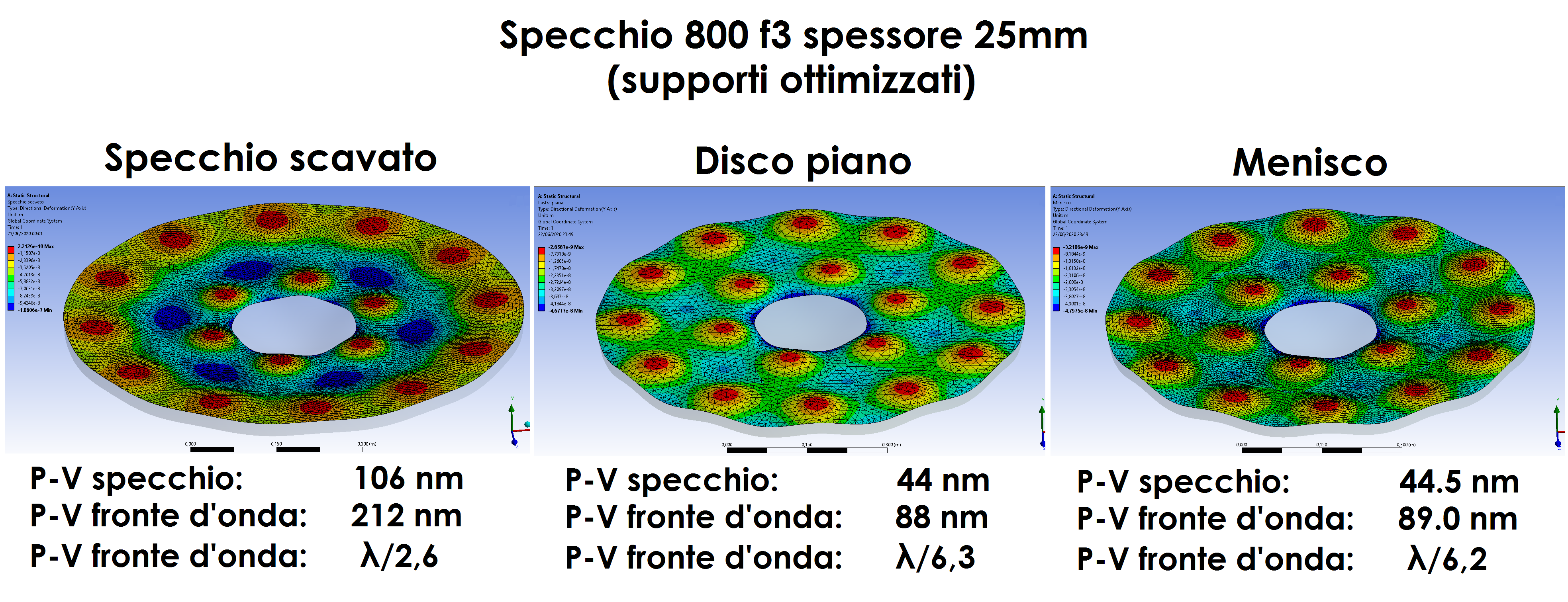

In the attached image I report 3 different cases compared:

the first with a mirror carved in a conventional way, blank da 800mm f3 spessore 25mm

The second with a flat disc, always 800mm in diameter and 25mm thick

The third with a meniscus always 800mm in diameter f3 25mm thick.

The conventional solution gives you a P-V error on the wave front of 212nm

only of deformation due to its own weight.

only of deformation due to its own weight.

The other two solutions also give absolutely unacceptable deformation values for an astronomical mirror, which makes it obvious, that 25mm thick is too small a thickness for this diameter (with cell a 18 support points, if you go up with the number of supports, I don't know what happens, but certainly the cell gets complicated a lot).

Another information that shows this simulation, is that a flat disc and a meniscus, they have substantially the same stiffness and show the same deformations under the pressure of gravity, which is to be expected given the small curvature of the meniscus with respect to the flat disc.A piece of advice I can give you instead, is to contact Schott directly, which can sell you an entire sheet of borosilicate (the slab is large eh, if I remember correctly, like 1200mmx3000mm), thicknesses from 35 at 53mm it seems to me, I go to memory, a cira 3000 euri. If you find anyone else interested, you can have various discs cut to waterjet, and then divide the expense.

Ciao

Mirco 26 June 2020 at 12:53 #11910

26 June 2020 at 12:53 #11910Thank you for taking the time to do the analysis – I did a similar thing with PLOP and it was clear from the start that a 25mm e’ tragically too thin.

I repeat – especially to myself ;) – that this should be considered a middle ground between an attempt and an experiment. When I see those who try their hand at uncharted terrain it usually takes longer’ of an attempt. And the second attempt e’ much more’ sent.

A positive result will be’ that we will perfect the processing machine and our master begins to get involved – he definitely wanted to scratch a little’ of glass.

The second / third analysis you do reiterates - as I already have’ seen elsewhere- that x computational analysis a meniscus behaves like a flat disk. The recruitment here and’ that the telescope e’ aimed at the zenith. When it's’ aimed at 45 degrees - just to give an example- the meniscus appears to be slightly higher. In addition, lateral support becomes relevant – until now I have been convinced by the whiffle-tree with Teflon supports on the center of gravity plane.

Ah, in brackets the cell will be’ until 27 points – compared to everything else it is not’ a great deal’ of complexity. I have the pieces laser cut and oh yeah’ took the spherical pads to connect all the triangles.

At Schott Italia I have tried more’ times a few weeks ago but no one answered – thanks anyway for the advice. I try again again

29 June 2020 at 22:27 #11911Hi Michele,

Yes, of course, the cell must be checked at all angles, however, it was so evident that the thickness was not adequate even only aimed at the zenith, that I have not continued further.

Cell a 27 points can definitely help, but I always find it hard to keep it in shape as you tilt it (I always talk about 25 mm eh).

Hi Michele, good continuation, I look curious, the various updates and the progress of the work

Ciao

Mirco30 June 2020 at 15:04 #11912A preview of the last work session:

https://i.postimg.cc/FsLQ6qpK/IMG-7543.jpg

I usually post updates here as well as on CN and SGL:

Instagram: #800mm_telescope

Facebook https://www.facebook.com/800mm.telescope

YouTube https://www.youtube.com/channel/UCC4…IGmvUwCV9ASGUQ -

AuthorPosts

- You must be logged in to reply to this topic.