- This topic has 5 replies, 3 voices, and was last updated 10 years, 5 months ago by

Giulio TiberinI .

-

AuthorPosts

-

12 October 2014 at 2:00 #4528

Among the excellent video of Gordon Waite point out this:

Interesting, in the first part of the trajectory generated by the COC rides with sub 7″ (35%) of the turntable, alternate with ran to W limited to the central area with modified patina in Stella. In this way Gordon manages to get a quick study of the center. The modification of the external area of the patina allows him to further concentrate the excavation action on the center, decreasing effectiveness on the outside mirror.

I do not know if it's just me, but the mixture of cerium seems a bit’ too thin, I do not see the friendly and soothing foam…

Also wondering if the black as pitch… pitch, is the same as that used in its Giulio “squares "Candy"”.

12 October 2014 at 23:51 #4540DILUTION: Your impression on the low density of the mixture of cerium oxide and water used by Gordon, is my. But I think everyone works in his own way.

(Beware, because it could not be cerium oxide but aluminum oxide…Alias corundum…alias emery (Emery), which has an abrasive power often desideratamente lower cerium oxide. And therefore it is also used more diluted to obtain a definitely excellent surface, despite the increasingly unkind, machined!)I would say for myself that, while when using the carborundum it is not to exceed well with the amount of abrasive for each dried (because it loses much of its cutting power to aggression and self-destruction of his own grain surplus, rather than useful for abrasion on the glass); For polishing, wherein the abrasive is encrusted in the pitch, I have always found it better with a creamy consistency just.

From my notebook of notes taken during my work (….because in the absence of information, one must inevitably experience !!) I found the right balance with a dilution of a spoonful of cerium oxide (or zirconium), with 2 tablespoons water.

And that little amount prepared from time to time I had enough for a’ now working on a mirror diameter 300mm.

I also noted that with a dilution of one to three, I did not get the beneficial foam that effectively distributes the abrasive, while dilution 1:2 it came by itself after twenty minutes of continuous work.

I also noted that with the zirconium oxide, for some strange reason, I could not get the famous foam, and then I gave it up in favor of normal oxide or refined cerium (Opaline).

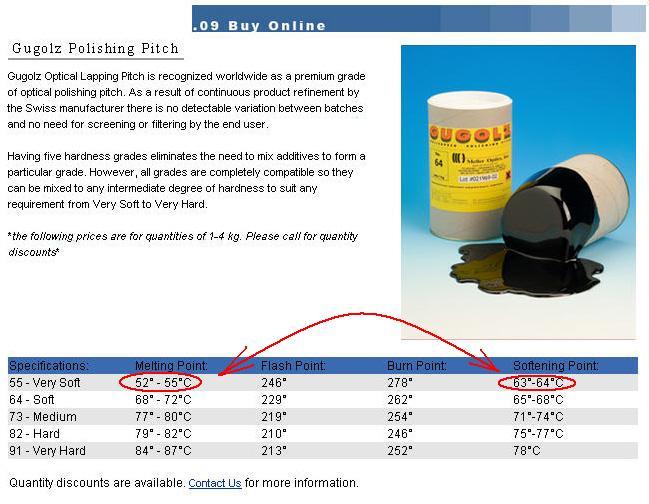

vs. Pitch hardness: That used to be Gordon's pitch black, and could be the Gugolz, which it is also the only one that I have used so far for my "candy", gradation #55 (which has the lowest softening point, because I scratch winter glass, when other sports to do the gymnastic movement are not comfortable).

The pitch black offers the advantage of being available in different shades, characterized by having a softening point stated, as seen from the following figure (except error exchange print, indicated by red arrows, where the melting temperature can not be lower than the softening).The indication of the softening temperature, He has made me prefer towards the use of rosin I, but I have never used, because it blends well above 100 ° C, ie even higher temperature of the hardest pitch black, and then (apart from the danger to the thermal chock in eventual direct casting on the tool, What I avoid with the production of notes “squares "Candy"” referred to in Article of this blog) It must be mixed with beeswax and / or turpentine and / or linseed oil experimentally to find a satisfactory hardness at the working ambient temperature, losing in this way a long time and not leaving a job precise recipe for the future.

14 October 2014 at 23:21 #4565I agree with what you said, I have always preferred a creamier liquid solution where I perceived a more effective action and adjust, even though from different parts I read that can be prepared with a minimum amount of cerium.

The indication of the softening temperature, He has made me prefer towards the use of rosin …

…It must be mixed with beeswax and / or turpentine experimentally to find a satisfactory hardness at the working ambient temperature,

Not to mention that the rosin, if excessively heated and brought to boiling temperature deteriorates rapidly becoming unusable, it seems that “crystallizes”.

The percentage of beeswax ( I remember that we talked about it long ago… ) It is always an unknown factor, I never got the same compound also using the same percentages, It has always of different hardness characteristics, I wonder if the same beeswax may have different characteristics in different productions, I would like to hear the opinion of Mauritius, who is experienced in this area, maybe I open a discussion on beeswax.

I would like to try the Gugolz, but they are not able to find sites of European sales, only overseas.

15 October 2014 at 9:14 #4569Ciao,

first some background on wax api.Non have a chemical

but I have the hobby of beekeeping 30 years.

Beeswax is produced by younger bees who in their abdominal glands to atrophy after 2 / 3 week of life.

Bees to pull off the wax from their abdomen oozing from the abdominal openings as flakes, and then with the legs to bring the jaws where it is chewed and softened to be able to be modeled.

The best wax (pure) e’ that the young bees use to seal the cells of the honeycombs full of mature honey at this stage and’ a translucent white, then you can take other colors according to the oily substances of pollen of the flowers that were bottinati.

I, for example after smelatura take this wax, and I boil and then cool down in the filter and focuses across the top and saw that’ more light water.

Then there are also polluted with propolis wax residues,pollen and cocoons of the larvae and I believe in these characteristics change.

One advice I can give and’ to go to a store and buy beekeeping 1 kg of waxy leaves which in theory should be pure (then it always depends on the honesty of those who produce them).

I hope I was helpful.maurizio

15 October 2014 at 14:04 #4570Very interesting, then find the waxy leaves ( of which I now discover the existence ) It means taking the purest, “the essence” Beeswax .

I am totally a layman, but it seemed that the beeswax normally found in the hardware is not then a product so “pristine”, maybe I'm wrong, but it is possible that, as Maurizio said, the external elements modify precisely those properties “softeners” and smoothness ( sorry if an improper use terminology ) that we are interested to work with rosin.Definitely a try to do, after finding a beekeeper in the area…

15 October 2014 at 16:37 #4571

15 October 2014 at 16:37 #4571The places where you could buy the Gugolz in Europe (..I am alone 2, one of which is an individual company), it is googling: OAMS glass Size – Astro Optics Moindrot Sebastian

-

AuthorPosts

- You must be logged in to reply to this topic.

[/url]

[/url]